Hey everyone, I need some help. I am trying to run a hydraulically driven motor like a bush hog on my l4740. Now I know I can get the pressure from my rear remotes or third function but the return line needs to go to sump. I do not like the idea of running the hose into the fill port for it will cause frothing in the fluid. The only option i can seem to come up with is to cut and tee into the steel line that comes from the back of the loader valve and goes to the tank. I cant find any open ports. Any thoughts?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Kubota L4740 return to sump

- Thread starter Josh1564

- Start date

- Views: 13058

-

- Tags

- kubota l4740

More options

Who Replied?

/ Kubota L4740 return to sump

#1

Leejohn

Elite Member

Maybe you could tee in at the loader valve and not cut any hard lines.

Dave M7040

Elite Member

- Joined

- Dec 10, 2012

- Messages

- 2,757

- Location

- Williamstown Ontario Canada

- Tractor

- Kubota M7040 Nuffield 465

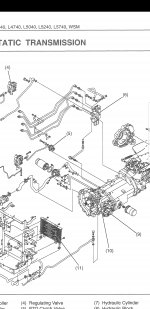

Look closely at your owners' manual. On my slightly larger M series, the rear remotes can deal with supply and return for a hydraulic motor.

I run my Samurai sickle mower this way.

In the attached image from my owners manual, it clearly shows one remote of a pair is pushing and the other returning to the sump.

This is not unlike a loader valve. When a cylinder is extending, the retract side of the cylinder is being routed to the sump by the loader valve.

Dave M7040

I run my Samurai sickle mower this way.

In the attached image from my owners manual, it clearly shows one remote of a pair is pushing and the other returning to the sump.

This is not unlike a loader valve. When a cylinder is extending, the retract side of the cylinder is being routed to the sump by the loader valve.

Dave M7040

Attachments

dstig1

Super Member

- Joined

- Apr 7, 2010

- Messages

- 5,605

- Location

- W Wisc

- Tractor

- Kubota L5240 HSTC, JD X738 Mower, (Kubota L3130 HST - sold)

A first concern is that i doubt you have enough flow in the tractor's hydraulics to run a bush hog. I have looked into similar uses regarding a rotary broom, and was advised that there is not enough flow to do that and still drive the tractor.

5030

Rest in Peace

- Joined

- Feb 21, 2003

- Messages

- 28,967

- Location

- SE Michigan in the middle of nowhere

- Tractor

- Kubota M9000 HDCC3 M9000 HDC

Most of the M series have a threaded boss tapped into the back PTO end cover just for returning fluid to the transmission case (sump if you want to call it that). Where my loader returns to on both my M's. Not sure if the smaller units have that but it's easy enough to drill and tap an access port in that location, though you would have to remove the rear cover so as not to contaminate the fluid inside.

Dave M7040

Elite Member

- Joined

- Dec 10, 2012

- Messages

- 2,757

- Location

- Williamstown Ontario Canada

- Tractor

- Kubota M7040 Nuffield 465

The minimum flow rate for the motor is 8 gpm

Dave, I thought I could return it through the remotes but the company advised against that.

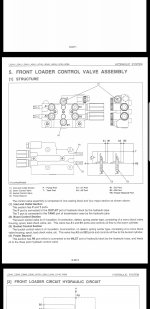

I have attached 2 screenshots of my loader valve from the WSM

View attachment 661980View attachment 661979

Could you post some info on the hydraulic side of your cutter. i.e. motor spec and model

Does the motor have a case drain?

You could always connect into the T line on your loader valve.

Running a high hydraulic flow though your system will start heating it up. You may find you need a cooler and fan for the return flow.

Dave M7040

jaydee325

Veteran Member

- Joined

- May 21, 2013

- Messages

- 1,206

- Location

- Casco, Mi

- Tractor

- John Deere X584 Garden Tractor & LS R3039H

Running a high hydraulic flow though your system will start heating it up. You may find you need a cooler and fan for the return flow.

Dave M7040

My thoughts exactly. Having a constant 8 gpm flow through the return on a rear remote is going to have a lot of restriction through the quick coupler and any other down stream choke points. That is going to make heat and probably why the manufacturer recommended against that.

I'm thinking the rear remotes on CUTs are primarily designed for intermittent use to extend and retract cylinders.

A self contained PTO driven hydraulic power pack rated for the desired flow may be the better option.

Have yall heard of the Laneshark. That is the fel bushhog l am referring to. I know they run them on tractors all the time and even much smaller tractors ( with a smaller hydraulic motor). They do not seem to have much experience with the grand L's. And not very responsive due to the COVID and everyone working from home. I also get no help from any dealer around. They all tell me it not possible to run a hydraulic motor off of a tractor, that is why most implements are pto driven.

The best place I can find to tie in is on the hard pipe from the loader valve to the sump.

The best place I can find to tie in is on the hard pipe from the loader valve to the sump.

Dave M7040

Elite Member

- Joined

- Dec 10, 2012

- Messages

- 2,757

- Location

- Williamstown Ontario Canada

- Tractor

- Kubota M7040 Nuffield 465

My thoughts exactly. Having a constant 8 gpm flow through the return on a rear remote is going to have a lot of restriction through the quick coupler and any other down stream choke points. That is going to make heat and probably why the manufacturer recommended against that.

I'm thinking the rear remotes on CUTs are primarily designed for intermittent use to extend and retract cylinders.

A self contained PTO driven hydraulic power pack rated for the desired flow may be the better option.

Another consideration, keeping in mind the owner plans on powering a heavy rotating cutter with lots of inertia, is the movement of any hydraulic control with the wrong spool is going to bring the motor to an instant stop and likely damage the motor or hydraulic system.

The following explains the difference:

Cylinder spool: work ports blocked in neutral. Motor spool: work ports connected to tank in neutral. ....

Dave M7040

Dave M7040

Elite Member

- Joined

- Dec 10, 2012

- Messages

- 2,757

- Location

- Williamstown Ontario Canada

- Tractor

- Kubota M7040 Nuffield 465

Any other options come to mind?

Also side question. What is the reason for not running a backhoe like the BH92 off of rear remotes?

For the TLB's the design sees the pump flow first directed to the BH valve and then, using a PB port in the hoe valve, send flow to the loader valve.

This is done to provide the minimum of pressure loss before reaching the hoe.

Also by reducing the number of relief valves before the flow gets to the BH, you can provide a higher operating pressure.

For example, M series kubota's typically send flow to the loader, (which has a relief valve) and then to the rear of the tractor where there is another relief valve for the 3 pt hitch and remotes. If the loader relief is set to say 2,500 psi, you can adjust the rear remote as tight as you want but the pressure will never be able to go about 2,500 psi because the loader relief, which also protects the PB circuit kicks in.

The typical rear remotes are getting hydraulic flow from a PB port on the loader valve.

You will note on tractors where the BH is removable, that the hydraulic power beyond loop has to be maintained with a length of hose whereas with rear remotes, you can just disconnect and forget it.

Dave M7040

Last edited:

Complete Turf Care

Veteran Member

- Joined

- Mar 31, 2013

- Messages

- 2,253

- Location

- South Louisiana

- Tractor

- 2022 Kubota Grand L6060 (no loader), 2017 Kubota Grand L6060, 2011 Kubota L5740 HSTC-3, 1997 Kubota M4700

I had a similar issue about 6 years ago. Here is a link to the thread we did on my issue. It's a pretty long thread, but hopefully it will help with your issue.

https://www.tractorbynet.com/forums/hydraulics/297573-laser-grading-hydraulic-valve-issue.html

https://www.tractorbynet.com/forums/hydraulics/297573-laser-grading-hydraulic-valve-issue.html

crazyal

Super Member

The front mount blower uses a hydraulic motor to rotate the chute. It uses 3 lines, two for pressure and a 3rd one that returns the fluid. I can look at my 4240 see how the factory does it.

crazyal

Super Member

[I had a similar issue about 6 years ago. Here is a link to the thread we did on my issue. It's a pretty long thread, but hopefully it will help with your issue.

https://www.tractorbynet.com/forums/...lve-issue.html]

CompleteLawnCare, did you have continuous hydraulic flow with your blade? Also are you still using it with the fluid returning through the fill port?

I worry about aerating the fluid and over heating the pump.

https://www.tractorbynet.com/forums/...lve-issue.html]

CompleteLawnCare, did you have continuous hydraulic flow with your blade? Also are you still using it with the fluid returning through the fill port?

I worry about aerating the fluid and over heating the pump.

Complete Turf Care

Veteran Member

- Joined

- Mar 31, 2013

- Messages

- 2,253

- Location

- South Louisiana

- Tractor

- 2022 Kubota Grand L6060 (no loader), 2017 Kubota Grand L6060, 2011 Kubota L5740 HSTC-3, 1997 Kubota M4700

[CompleteLawnCare, did you have continuous hydraulic flow with your blade? Also are you still using it with the fluid returning through the fill port?

I worry about aerating the fluid and over heating the pump.[/QUOTE]

I would not say it was continuous flow, but I would consider it intermittent flow. As I am driving along, the blade automatically tries to stay at the same level, therefore it will automatically raise and lower many times during the process. I believe this would potentially cause more heat than continuous flow would cause.

Yes, I am still using it the same way as I posted 6 years ago, and have not had any issues since then. I would guess that I have 200-300 hours using it this way.

I have had some other issues with that tractor and I am considering using my L6060 for laser grading in the future. If I do use the L6060, I will attempt to just bypass the quick coupling fitting on the 'return' line. In other words, I will not dump the 'return' oil into the fill port, but will remove the quick coupling and connect the 'return' hose behind it.

I have purchased the fitting I will need for this, but I have not tried it yet.

Below are where I plan to install this fitting when I do try to use it on my L6060

I worry about aerating the fluid and over heating the pump.[/QUOTE]

I would not say it was continuous flow, but I would consider it intermittent flow. As I am driving along, the blade automatically tries to stay at the same level, therefore it will automatically raise and lower many times during the process. I believe this would potentially cause more heat than continuous flow would cause.

Yes, I am still using it the same way as I posted 6 years ago, and have not had any issues since then. I would guess that I have 200-300 hours using it this way.

I have had some other issues with that tractor and I am considering using my L6060 for laser grading in the future. If I do use the L6060, I will attempt to just bypass the quick coupling fitting on the 'return' line. In other words, I will not dump the 'return' oil into the fill port, but will remove the quick coupling and connect the 'return' hose behind it.

I have purchased the fitting I will need for this, but I have not tried it yet.

Below are where I plan to install this fitting when I do try to use it on my L6060

Last edited:

Here are some similar links:

- Replies

- 1

- Views

- 717