rScotty

Super Member

- Joined

- Apr 21, 2001

- Messages

- 9,663

- Location

- Rural mountains - Colorado

- Tractor

- Kubota M59, JD530, JD310SG. Restoring Yanmar YM165D

Thanks for the explanations. My L48 also has 3 QDç—´ for the backhoe. I am a complete novice with hydraulics. I think I understand what youæ±*e saying regarding the 2 QDç—´ that operate the digging action of the hoe...that one is the supply from the pump and one is the return. And what you said about downstream cylinders not working while the top link cylinder is actuated makes sense to me too.......because fluid operating the top link cylinder returns to the pump and never makes it to downstream cylinders, is that correct? I think I remember reading that one advantage of the L48 over other compact TLBç—´ was that it had 2 pumps for the backhoe so it could operate with a more complex motion ......closer to that of a full sized backhoe......than compact hoes with only one pump for the hoe. That 3rd QD supplies the hydraulics to swing the boom. If...if I wanted to add a second cylinder for a true top & tilt, could I do that using the 3rd QD? But I don稚 understand why there is not a 4th QD that would return fluid to the pump when swinging the boom. If there is a quick explanation that won稚 take too much of your time, I壇 greatly appreciate it.

What you want to do can be done in several different ways.

Probably one of the easiest is to simply divert flow using a T from the front remotes. This is easily done by several methods. Keep in mind that when you put a T in an open flow hydraulic system you are creating an alternate path in a system designed to feed all the flow into a whichever path is less restrictive. So the path not used needs to be either blocked or restricted. This can be done by a manual switching valve, by a priority valve, or even by the hydraulic control valve that you use to operate the cylinder itself....but only if that control valve has a "power beyond" option and the plumbing is done properly. Return hose diameter is important for long runs.

It is important that the flow path that you choose to use must have it's own valve as well as proper return paths both from the valve and from the working cylinder.

I'm sure that something similar could be done using those attractive rear mounted quick disconnect backhoe pressure/return connections for digging and swing flow..... but I don't know which is what with those rear connectors and would be reluctant to do it myself without first studying the system and then drawing out a flow diagram showing EXACTLY what I decided to do. But there's not a reason in the world why you can't do it.

I recommended looking at the front remote first because it is a simpler single system with more than enough flow and only costs you a little more in hose length - hose which you would probably want to use anyway to get the control valve forward where it is more accessible. Remember that return hoses are generally larger diameter than pressure feed hoses

I think you would find it an advantage to get the Kubota workshop manual for you L48; & advise everyone who enjoys tractor mechanics to invest in the manufacturer's workshop manual.

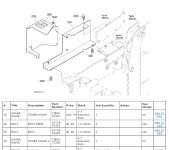

I have one for our M59 and it has an excellent chapter on the hydraulic system with good illustrations. One for the L48 would probably answer all of your questions.

Another thing that will help is to learn how to read a hydraulic flow diagram in schematic form. The workshop manual has that diagram as well. If you simply sketch out your proposed hydraulic circuit in schematic fashion it is hard to go wrong.

rScotty