Hi again,

I have a model 100 loader on my 2840 Montana. Curved lift arms.

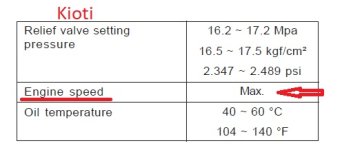

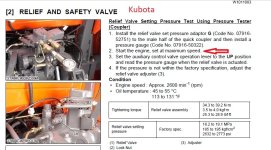

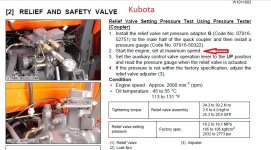

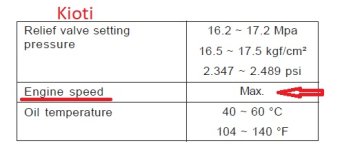

I want to have better lift capacity for my loader. I believe I have a low relief valve pressure issue and wonder what is the best way to check the relief pressure.

What is the proper way to check and set the relief pressure. IE: Shim size in relationship to pressure change. I don't want to over burden the system just want to be sure I'm in the range that I should be in as far as pressure vs lift capacity.

In a previous post I read where the 4550 has the same model 100 loader. The 4550 can lift more than twice the load that I can with mine so the loader is not the limitation. It seems the hydraulics and the chassis are the limiting factors. I added #300 suitcase weights to my box blade and have become keenly aware of how little weight the loader can lift (#500 with my forks, if that). A full bucket of dry 3/8" gravel will not budge and adds no load to the engine rpm. I think it is an issue with a low relief valve pressure setting.

The 3 point seems so much more powerful and drops the engine rpm when lifting heavy loads. The loader does not change the engine rpm even when at the relief bypass valve pressure limit.

What pressure should I see and what is the range of adjustment for the model 100 loader vs lift capacity?

PS: I love my tractor and so far I don't know how I lived without my tractor in the past.

Thanks.

I have a model 100 loader on my 2840 Montana. Curved lift arms.

I want to have better lift capacity for my loader. I believe I have a low relief valve pressure issue and wonder what is the best way to check the relief pressure.

What is the proper way to check and set the relief pressure. IE: Shim size in relationship to pressure change. I don't want to over burden the system just want to be sure I'm in the range that I should be in as far as pressure vs lift capacity.

In a previous post I read where the 4550 has the same model 100 loader. The 4550 can lift more than twice the load that I can with mine so the loader is not the limitation. It seems the hydraulics and the chassis are the limiting factors. I added #300 suitcase weights to my box blade and have become keenly aware of how little weight the loader can lift (#500 with my forks, if that). A full bucket of dry 3/8" gravel will not budge and adds no load to the engine rpm. I think it is an issue with a low relief valve pressure setting.

The 3 point seems so much more powerful and drops the engine rpm when lifting heavy loads. The loader does not change the engine rpm even when at the relief bypass valve pressure limit.

What pressure should I see and what is the range of adjustment for the model 100 loader vs lift capacity?

PS: I love my tractor and so far I don't know how I lived without my tractor in the past.

Thanks.