ScipioUSA

Silver Member

- Joined

- Jul 29, 2019

- Messages

- 112

- Tractor

- MF 20 Industrial, Ghosts of Farmalls Past

Not sure if anyone saw my other post in the Parts/Repairs section, but its looking like I need to split my MF 20 Industrial. I have never split this tractor before, and its sure gonna be a real peach trying to do it with the loader on there still.

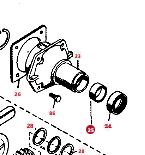

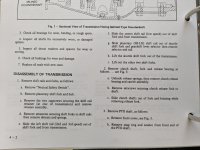

Anyway, my machine has the 3 cylinder Perkins gas, and I am mostly wondering what anyone could suggest that I replace while I have it apart. I think my input shaft seals are leaking, so that means I have to split it twice, once for engine/transmission, and then transmission/rear end. It has the six speed shuttle transmission, so to pull the input shaft, I have to pull the front PTO shaft out the back of the transmission. Such fun.

Any thoughts on bits and pieces or things that I should make sure to investigate and replace "while I am in there"? I am not 100% that I am going to do this work myself yet, and know some of this will have to wait until I can put eyes on it.

Would appreciate any thoughts in the meantime on what would be good to have on hand or price out ahead of time.

Thanks!

Anyway, my machine has the 3 cylinder Perkins gas, and I am mostly wondering what anyone could suggest that I replace while I have it apart. I think my input shaft seals are leaking, so that means I have to split it twice, once for engine/transmission, and then transmission/rear end. It has the six speed shuttle transmission, so to pull the input shaft, I have to pull the front PTO shaft out the back of the transmission. Such fun.

Any thoughts on bits and pieces or things that I should make sure to investigate and replace "while I am in there"? I am not 100% that I am going to do this work myself yet, and know some of this will have to wait until I can put eyes on it.

Would appreciate any thoughts in the meantime on what would be good to have on hand or price out ahead of time.

Thanks!