Your relief valve in your circuit is working correctly.

When you hear your relief valve working, when you put your thumb against the bucket, 40+ Litres/min ( from the pump ) is flowing through your relief valve.

When you put the bucket up against the thumb, and the cylinder comes in, your relief valve has worked correctly, except you haven't got 40 Litres/Min going through it, just 50ml ( as a guess )has relieved back to tank.

Do you need a relief valve on the rod side of the cylinder? Depends

If you are going to use the thumb as intended, then NO.

However, if you are going to use it to lift, or strap it to the bucket and then unintentionally rotate the bucket or put Quick disconnects or flow control valves on the rod side, then I would say YES, due to Pressure Intensification.

If you had quick disconnects or a flow control valve on the rod side and it was not connected properly or the rod side oil was blocked from going back to tank, then pressure intensification will happen.

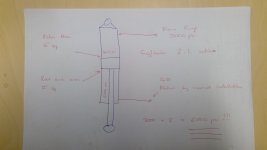

If you have a 2:1 ratio cylinder and you put 3000psi on the piston side and the rod side oil could not return to tank, then pressure will increase to 6000psi ( 3000 x 2 = 6000). If your hose is rated for 4000 psi and you now have 6000 psi on it, the hose can burst and if someone is hit by high velocity oil, then an oil injection can incur.

All the best

Duff

When you hear your relief valve working, when you put your thumb against the bucket, 40+ Litres/min ( from the pump ) is flowing through your relief valve.

When you put the bucket up against the thumb, and the cylinder comes in, your relief valve has worked correctly, except you haven't got 40 Litres/Min going through it, just 50ml ( as a guess )has relieved back to tank.

Do you need a relief valve on the rod side of the cylinder? Depends

If you are going to use the thumb as intended, then NO.

However, if you are going to use it to lift, or strap it to the bucket and then unintentionally rotate the bucket or put Quick disconnects or flow control valves on the rod side, then I would say YES, due to Pressure Intensification.

If you had quick disconnects or a flow control valve on the rod side and it was not connected properly or the rod side oil was blocked from going back to tank, then pressure intensification will happen.

If you have a 2:1 ratio cylinder and you put 3000psi on the piston side and the rod side oil could not return to tank, then pressure will increase to 6000psi ( 3000 x 2 = 6000). If your hose is rated for 4000 psi and you now have 6000 psi on it, the hose can burst and if someone is hit by high velocity oil, then an oil injection can incur.

All the best

Duff