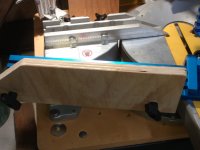

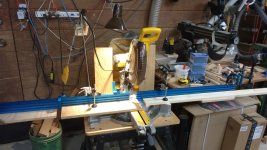

Pat, you're welcome; I took a few pics yesterday, most of the non-original parts are available at Rockler. For now, the toggle clamps aren't perfect - I eventually want to adapt those drill press cam clamps. Still, the pivoting action of the toggles DOES tend to pull the material up against the fence. The two holes in the lower fence of the saw had no known reason to be there, so I enlarged 'em enough for the 1/4" T bolts. The blue extrusions are 3" x 36".

One advantage of this setup is flexibility; you can have as many flip stops or holddowns as will fit, and place them anywhere it's needed. My saw didn't come with any table extensions, so I added a couple that mount to the bottom groove on the extrusions.

All the cute knobs and T bolts are part of ANOTHER Rockler item, the jig/fixture kit; it's available in 1/4" and 5/16", I bought one of each.

Again, this can get kinda expensive - at the time, I was working 12 hour days, sometimes 6 days a week - less shop time (for "roll yer own" mods), but bigger O.T checks

Anyway, the pics - any further questions, just ask... Steve

Forgot to mention; on the toggles, note that the standard hex nuts are NOT used for height adjustment; it's a PITA to keep wrenches around for EVERYTHING, so the under side now has a wing nut, top side is a knurled knob (from the fixture kit) - in operation I lock the toggle down, back off the knob, spin the wing nut up against the toggle, 'nuther couple turns for some pressure (with a piece of the material under the clamp, duh), then hold the wing nut and snug up the upper knob. Quicker to do than it was to type...