J_J

Super Star Member

- Joined

- Sep 6, 2003

- Messages

- 18,973

- Location

- JACKSONVILLE, FL

- Tractor

- Power-Trac 1445, KUBOTA B-9200HST

Not that this makes a hill of beans, but on my 1850, A hose goes to the front wheel, and then a hose goes to the back wheel, and then a hose goes back to the pump. - Same on the other side. I am still trying to track down the relief hoses and where they all go to...

Carl,

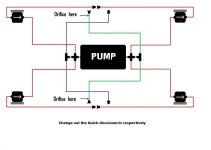

There are no relief hoses on the wheel motors. You have pressurized fluid going to the motors, and used fluid going back to the input of the pump. You maybe referring to the case drains on the wheel motors, as Snowridge mentioned. I believe all case drains go back to the pump case drain and then the fluid goes from the pump case drain to the cooler. Some of the wheel motors used on PT's do not have case drains. On my 1445, all the case drains are collected in a manifold and one line goes to the pump case.