Stampeder

Gold Member

- Joined

- Dec 2, 2006

- Messages

- 319

- Location

- East Texas

- Tractor

- Montana 4940C, FEL, Quick change 3 point factory hitch, pallet forks, grapple, 50 gal tank sprayer, Bush Hog PHD

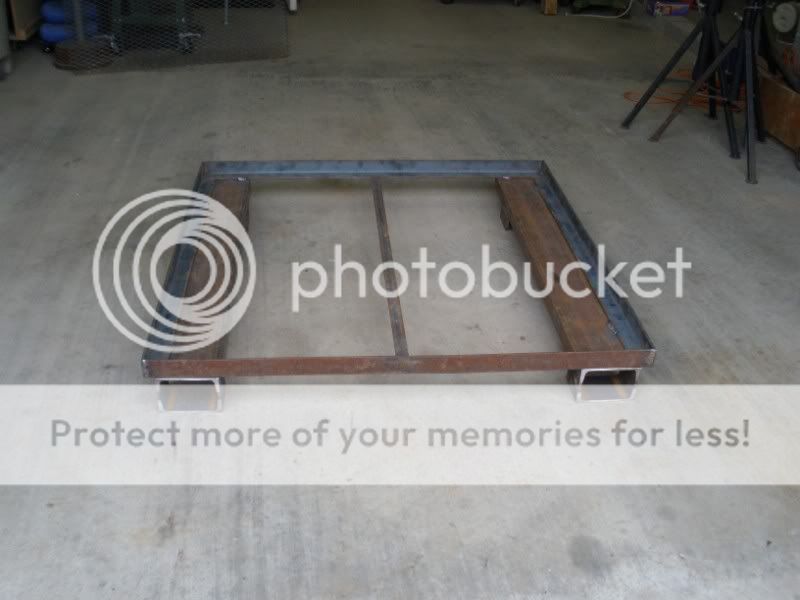

Here's my take on a manlift I'm building. I've got lots of tall trees to be trimmed, a 15 foot high gate that needs painting and a bunch of other tall projects to do so I've been wanting to get this done for a while.

I'll post pictures as this progresses but here's the first of them:

This is the beginning. The base is 2x2 angle. The bottom has two 6 inch channel iron guide for the forks on my front end loader. Because my forks are 4 inches wide and 2 inches high at the root I had to weld on 4 inch pieces as you can see below to form boxes. A side benefit of this is they will become the mount for casters I will be adding so moving this around in the barn will be easier.

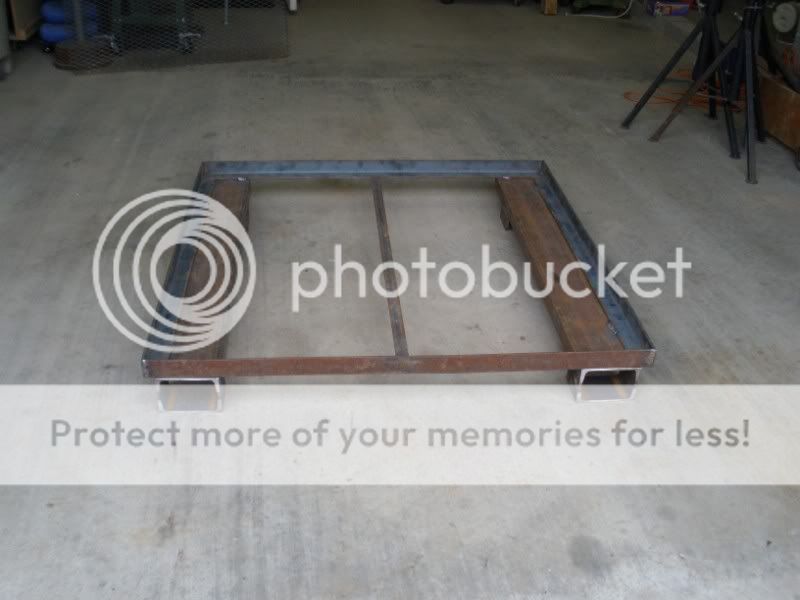

This is a side view so you can see where I welded the additional channel pieces.

Here the floor is added as well as the floor cross bracing. The floor is of expanded steel mesh. The uprights are 1.5x1.5 angle.

I may add a quick change front end to this so I can just hook up to it rather than having to use the forks all the time. The jury is still out on this one though.

I'll take some pictures today as I'm a little further on than in these.

Enjoy.

Glenn.

I'll post pictures as this progresses but here's the first of them:

This is the beginning. The base is 2x2 angle. The bottom has two 6 inch channel iron guide for the forks on my front end loader. Because my forks are 4 inches wide and 2 inches high at the root I had to weld on 4 inch pieces as you can see below to form boxes. A side benefit of this is they will become the mount for casters I will be adding so moving this around in the barn will be easier.

This is a side view so you can see where I welded the additional channel pieces.

Here the floor is added as well as the floor cross bracing. The floor is of expanded steel mesh. The uprights are 1.5x1.5 angle.

I may add a quick change front end to this so I can just hook up to it rather than having to use the forks all the time. The jury is still out on this one though.

I'll take some pictures today as I'm a little further on than in these.

Enjoy.

Glenn.