jgrreed

Platinum Member

OK guys, I stopped by the shop today to see what's gone on so far on adding my new circuits. There was a small kerfuffle re: the cost of the install, so I was too flustered to snap pics of the tractor, but I'll get those to you soon.

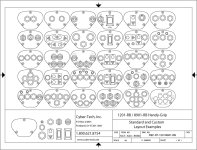

In the pic below are the bits of that I received from Otto for my controls and grips. A big thanks to Peter at Interior Electronics in Kelowna for his help in getting the parts, and to Steve Redlich at Otto for his coaching in what I need.

On the left are the grips with the faceplates detached (the second grip is at the shop for sizing). The sketch is how I'm going to cut in the holes for the rocker switches. The lone rocker on the lower left is the ON/OFF/ON switch that I'm going to use for the continuous ON circuit if I ever build a hydraulically powered weed wacker. It will go on the dash near the between the steering wheel and the throttle. The yellow pushbutton is for my horn project, which I'll deal with when the summer comes. The row of 5 rockers are the momentaries that are going to run the circuits. Below them are the gaskets to seal up the switches.

I'm about to start drawing and cutting..... wish me luck!!! Pics to follow.

-Jer.

In the pic below are the bits of that I received from Otto for my controls and grips. A big thanks to Peter at Interior Electronics in Kelowna for his help in getting the parts, and to Steve Redlich at Otto for his coaching in what I need.

On the left are the grips with the faceplates detached (the second grip is at the shop for sizing). The sketch is how I'm going to cut in the holes for the rocker switches. The lone rocker on the lower left is the ON/OFF/ON switch that I'm going to use for the continuous ON circuit if I ever build a hydraulically powered weed wacker. It will go on the dash near the between the steering wheel and the throttle. The yellow pushbutton is for my horn project, which I'll deal with when the summer comes. The row of 5 rockers are the momentaries that are going to run the circuits. Below them are the gaskets to seal up the switches.

I'm about to start drawing and cutting..... wish me luck!!! Pics to follow.

-Jer.