EddieWalker

Epic Contributor

Ten years ago I proposed to my wife. I asked her where she wanted to get married, and she said that she wanted it to happen at the pond. When I built the pond, I created a peninsula to build a gazebo on, but never got around to building it. So I drew some designs out for her to look at, she picked one that I liked a lot too, and the race was on to build it before our Wedding Day.

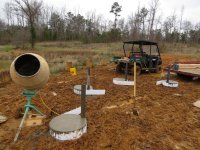

The before picture of where it's going to be built

After building the Pond, and after it was all full and happy, we had a really hot and dry summer that evaporated 8 feet of water. After that, I built a 2 foot concrete dam on my spillway to raise the overall water level two more feet. My thinking was the more water I had, the longer it would take to get back down to where it was that Summer.

This created an unforeseen problem for the Gazebo. The water level now went over the peninsula when the pond was full!!

My only solution was to build up the peninsula 2 feet higher. I put my dad to work hauling the dirt on the backhoe. Then I spread it with the dozer. Like everything, this took a lot longer then I had hoped for.

The before picture of where it's going to be built

After building the Pond, and after it was all full and happy, we had a really hot and dry summer that evaporated 8 feet of water. After that, I built a 2 foot concrete dam on my spillway to raise the overall water level two more feet. My thinking was the more water I had, the longer it would take to get back down to where it was that Summer.

This created an unforeseen problem for the Gazebo. The water level now went over the peninsula when the pond was full!!

My only solution was to build up the peninsula 2 feet higher. I put my dad to work hauling the dirt on the backhoe. Then I spread it with the dozer. Like everything, this took a lot longer then I had hoped for.