MicroPilot

Veteran Member

I had posted this in the Century forum but didn't get any repsonses. I wanted to see what you guys thought before I called my dealer.

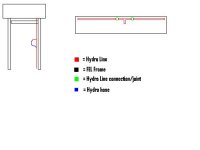

I removed my loader for the first time tonight and nearly broke a hydraulic line!

On the right loader arm on the inside there is a T connector that sticks out to the left, into the area between the arms. The brush guard got caught on this and would have ripped it loose if I hadn't been going very slow. Is this the normal way these loaders are plumbed? I doubt it just because of what I experienced. Can I just turn this T connector out of the way? I'm not familiar with how connections are made with hydraulic plumbing. I guess I might need to post a pic to show what I'm talking about.

I have attached a crude drawing until I can get hoem and get some pics.

I removed my loader for the first time tonight and nearly broke a hydraulic line!

On the right loader arm on the inside there is a T connector that sticks out to the left, into the area between the arms. The brush guard got caught on this and would have ripped it loose if I hadn't been going very slow. Is this the normal way these loaders are plumbed? I doubt it just because of what I experienced. Can I just turn this T connector out of the way? I'm not familiar with how connections are made with hydraulic plumbing. I guess I might need to post a pic to show what I'm talking about.

I have attached a crude drawing until I can get hoem and get some pics.