Hi all,

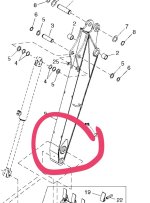

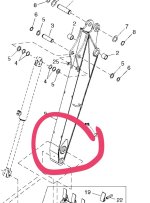

Need some advice RE: the backhoe arm on my JD 110. The lower pin [circled in diagram] is pretty loose, but when I checked the diagram, I didn't see a serviceable bushing, just a pin. Is this a repairable item or does JD recommend replacing the whole arm? It's clear the PO neglected greasing this particular pivot!

Thanks!

Need some advice RE: the backhoe arm on my JD 110. The lower pin [circled in diagram] is pretty loose, but when I checked the diagram, I didn't see a serviceable bushing, just a pin. Is this a repairable item or does JD recommend replacing the whole arm? It's clear the PO neglected greasing this particular pivot!

Thanks!