IHDiesel73L

Silver Member

- Joined

- May 13, 2010

- Messages

- 167

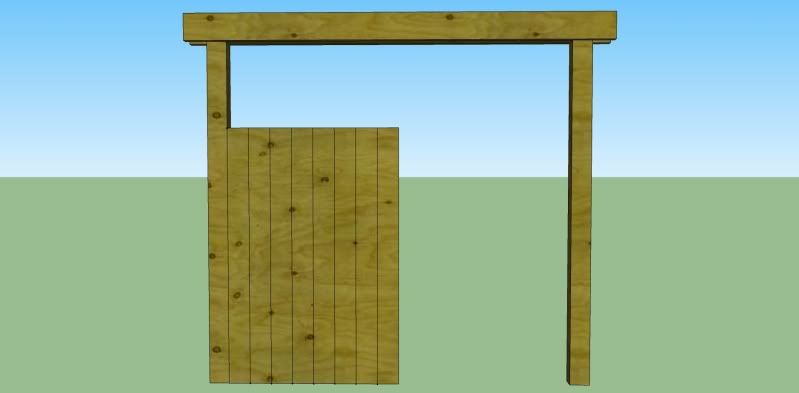

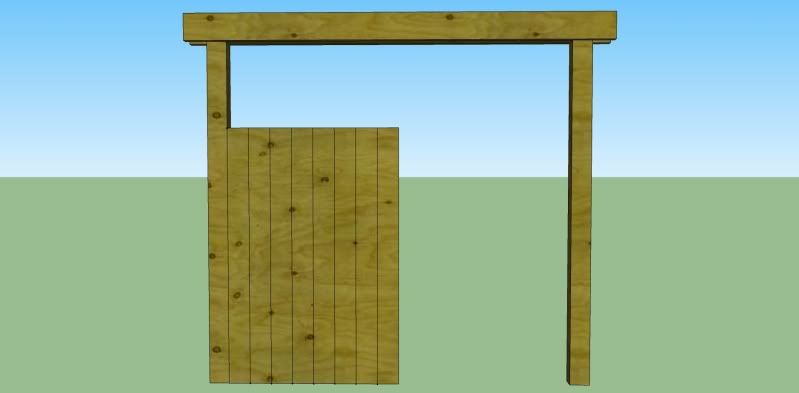

I am constructing a gate with a kind of archway over it because I want to be able to hang/hoist things from it if need be. One of the reasons I'm doing this is so that I have a place to hang deer before butchering which it can certainly handle, but I have a habit of overbuilding things, so I wonder how much I weight it will support? For example, could I lift the front end of a compact utility tractor? Could I pull a small block Chevy with it, etc...? Here is a sketchup representation of what I'm building:

I've already got the 4 x 6 posts in the ground. They are buried about 3' 6" on what seems to be solid and relatively undisturbed heavy clay soil. I dug the holes 4' deep and added 6" of gravel to the bottoms to facilitate drainage. This weekend I'll be adding the lintel on top which will consist of a 4 x 6 sandwiched between two 2 x 8s. The 4 x 6 lintel will rest on the tops of the 4 x 6 posts (a deviation from the drawing-I just decided that last night) and Timberlock fasteners will be driven through the top down into each post. After that, the 2 x 8s will be screwed to each side using 3" coated deck screws. Part of the function of the 2 x 8s is to provide a finished look, but they should also provide quite a bit of stiffness also.

I tried looking online for information about the strength of wood beams, and found lots of charts and formulas, but I really don't understand them well enough to use the information. All of the lumber is pressure treated Southern Yellow Pine. The unsupported span of the beam is 8' 1". I'm just trying to get a rough estimate of how much weight I can safely support with this. For example, a SBC with a cast iron intake, exhaust manifolds, etc...comes in at just shy of 600lbs, vs. the 7.3L Powerstroke in my truck which weighs nearly 1000lbs fully dressed :shocked: Any ideas?

I've already got the 4 x 6 posts in the ground. They are buried about 3' 6" on what seems to be solid and relatively undisturbed heavy clay soil. I dug the holes 4' deep and added 6" of gravel to the bottoms to facilitate drainage. This weekend I'll be adding the lintel on top which will consist of a 4 x 6 sandwiched between two 2 x 8s. The 4 x 6 lintel will rest on the tops of the 4 x 6 posts (a deviation from the drawing-I just decided that last night) and Timberlock fasteners will be driven through the top down into each post. After that, the 2 x 8s will be screwed to each side using 3" coated deck screws. Part of the function of the 2 x 8s is to provide a finished look, but they should also provide quite a bit of stiffness also.

I tried looking online for information about the strength of wood beams, and found lots of charts and formulas, but I really don't understand them well enough to use the information. All of the lumber is pressure treated Southern Yellow Pine. The unsupported span of the beam is 8' 1". I'm just trying to get a rough estimate of how much weight I can safely support with this. For example, a SBC with a cast iron intake, exhaust manifolds, etc...comes in at just shy of 600lbs, vs. the 7.3L Powerstroke in my truck which weighs nearly 1000lbs fully dressed :shocked: Any ideas?