Gary_in_Indiana

Elite Member

- Joined

- Apr 22, 2002

- Messages

- 3,373

- Location

- Fort Wayne, IN

- Tractor

- John Deere 4200 MFWD HST w/ JD 420 FEL w/ 61" loader bucket & toothbar & JD 37 BH w/ 12" bucket

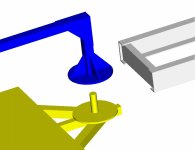

We're thinking the same here. I was thinking I'd have to remove the upright to turn it the 180 degrees because I'd be using 4 x 4 x 1/4 square tube over something like 3 1/2 x 3 1/2 square bar stock.

Your way has it so I'd just remove pins and spin it around then replace pins to lock it in place, right? Are you talking about using round stock there or what? That's where I lost you.

The drawings are great. Thanks.

Your way has it so I'd just remove pins and spin it around then replace pins to lock it in place, right? Are you talking about using round stock there or what? That's where I lost you.

The drawings are great. Thanks.