lzicc

Platinum Member

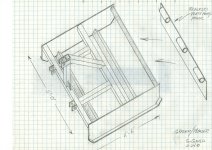

I am looking for something to grade my limestone driveway and was looking at a land grader. I think this would work well. Has anyone built one? It looks pretty basic to build, just trying to get some ideas. The blades look like they are curved, not sure if this is just the way the pics look or if they need to be curved. I'm am also trying to find out how far the blades go below the sides.

http://www.(Temporarily blocked due to reports of company closure)/v/vspfiles/photos/KK-Pro-Dual-Edge-Land-Grader-2.jpg

http://www.(Temporarily blocked due to reports of company closure)/v/vspfiles/photos/KK-Pro-Dual-Edge-Land-Grader-2.jpg