boggen

Elite Member

- Joined

- Feb 22, 2011

- Messages

- 3,829

- Location

- Trivoli, IL

- Tractor

- SSTT (Sideways Snake Tain Tractor) and STB (sideways train box) tractor, dirt harvester

Boggen, I think I understood Snowman say that he is using grade 2 bolts and his tractor is marginally underpowered for the size of the mower he has. His problem is that the bolts are not shearing before his tractor stalls when he hits obstacles.

Given that, sticking with the grade 2 bolt will not protect his tractor since it is already proven to shear at a higher level than necessary.

I concede that cutting a bolt does not provide accurate shear specifications, but then is that necessary or is getting in the ballpark good enough? Sure it might shear too soon from time to time, but that is better than not shearing at all as is the case with the unmodified bolt. Without an engineering analysis of his load and tractor capabilities it is impossible to know the exact shear strength required, so best guess is the best approach I can think of to keep working and dial in an adequate protection comfort level. It will take a bit of trial and error, but each trial will be less risky than continuing on as he has with the existing grade 2 bolts that have not sheared. Don't you think?

i have sheared bolts in half. that were not meant to be shear bolts! (frowns) just because they got a little loose the vibrations alone from mowing acted like a saw zaw and cut the bolts in half.

i have seen a few tractors limping back to the shed. with only half of the PTO shaft. do to the shear pin sheared away! and without them realizing it. the back half of PTO shaft fell off as well and went missing some place. retaining ring to hold shaft on was gone as well.

i am hesitant. to say cutting a grove in a bolt. you allow more play within the hole the sheer bolt goes through. that can cause oval of the holes and long term could result in not needing a grove a bolt. due to bolts just being sheared in half or i should say cut in half by pure vibrations alone.

i am hard on equipment. i run things to there limits at times. and at times keep pushing the limits till something does break or the job gets done. also not a real big fan. of possible parts flying out like a bullet when they do break. have had enough rocks shoot out from under a finishing mower deck.

being able to know after a couple trail and errors with a slip clutch. and then going back to that setting each year during maintance. and knowing and being more able to count on when things do slip. to me is a more reliable piece of equipment. vs relying on luck of non stop trail and error. and trying to find the shear pins after a year or two some place in the grage. (ya i labeled the box) but which box among all the other boxes of bolts, nails, etc... or did i place it....

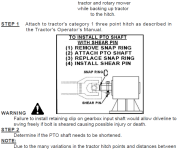

picture is from www.kingkutter.com rotory kutter manual