Ken M

New member

For your entertainment.....

After looking for a small used front end loader that I could afford, I found a 1998 New Holland TC21 the end of 2013. It had about 1200 hours on it, 9 x 3 gear transmission, had not been well maintained and had never seen a barn or garage so it is a bit weathered but it was within my price range. (that's another story). I don't have indoor storage either so I used a tarp until just recently when I put up a hoop shelter that I could drive under. Much better but as the photo shows it's not exactly how I envisioned it being used.

About mid October I had it out while cleaning out some old hedge stumps. It was in 4wd and as I drove it out of a rough uneven spot I heard a loud crunching sound and the machine came to an abrupt stop. Not good. I managed to get it free and very slowly back to the garage. Definitely a problem in the front differential. I blocked the tractor up and started the tear down. It's never a good thing when you drain the oil and get chunks of metal coming out. I had to remove the entire axle. The cross shaft in the differential that holds the side gears had broken and elongated it's mounting holes in the housing. Amazingly enough all the gears were still ok. Actual parts needed were about $225 but all of the seals and o-rings had to be replaced and they are all non-standard sizes so I had to also purchase from the dealer. Two seals for the king pins were $43 each!! Total repair $452 plus $25 for a manual.

So after all this work I take the tractor out for a test drive. In 2wd all is good and running smooth. I engage the 4wd and have crunching in the rear transmission!! I was afraid of this....the 2 gears in the rear that engage the front drive are also missing some teeth. Whoa is me. Discouraged, I talked to a mechanic at the dealer to see what kind of a job this was going to be. Ball park estimate is 6 hours for tear down, 6 hours to put together plus whatever time needed in the tranny plus parts of course. Oh, and this is at $80 per hour. Not picking on the dealer mind you. So it comes down to this...If I fix it myself I can still probably sell machine for about what I have in it. And I guess I'm a DIY kind of guy anyway. So...purchased the manual.

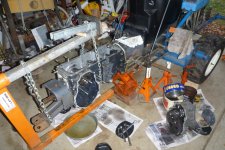

Tractor is stripped down. Eight more bolts and tranny will come free of clutch housing so I can pull shafts out. I see 2 drive gears without teeth. About $95 for both. Two other gears with shift grinding damage ...may not replace. Probably some seals. What a job! Stay tuned........Ken

After looking for a small used front end loader that I could afford, I found a 1998 New Holland TC21 the end of 2013. It had about 1200 hours on it, 9 x 3 gear transmission, had not been well maintained and had never seen a barn or garage so it is a bit weathered but it was within my price range. (that's another story). I don't have indoor storage either so I used a tarp until just recently when I put up a hoop shelter that I could drive under. Much better but as the photo shows it's not exactly how I envisioned it being used.

About mid October I had it out while cleaning out some old hedge stumps. It was in 4wd and as I drove it out of a rough uneven spot I heard a loud crunching sound and the machine came to an abrupt stop. Not good. I managed to get it free and very slowly back to the garage. Definitely a problem in the front differential. I blocked the tractor up and started the tear down. It's never a good thing when you drain the oil and get chunks of metal coming out. I had to remove the entire axle. The cross shaft in the differential that holds the side gears had broken and elongated it's mounting holes in the housing. Amazingly enough all the gears were still ok. Actual parts needed were about $225 but all of the seals and o-rings had to be replaced and they are all non-standard sizes so I had to also purchase from the dealer. Two seals for the king pins were $43 each!! Total repair $452 plus $25 for a manual.

So after all this work I take the tractor out for a test drive. In 2wd all is good and running smooth. I engage the 4wd and have crunching in the rear transmission!! I was afraid of this....the 2 gears in the rear that engage the front drive are also missing some teeth. Whoa is me. Discouraged, I talked to a mechanic at the dealer to see what kind of a job this was going to be. Ball park estimate is 6 hours for tear down, 6 hours to put together plus whatever time needed in the tranny plus parts of course. Oh, and this is at $80 per hour. Not picking on the dealer mind you. So it comes down to this...If I fix it myself I can still probably sell machine for about what I have in it. And I guess I'm a DIY kind of guy anyway. So...purchased the manual.

Tractor is stripped down. Eight more bolts and tranny will come free of clutch housing so I can pull shafts out. I see 2 drive gears without teeth. About $95 for both. Two other gears with shift grinding damage ...may not replace. Probably some seals. What a job! Stay tuned........Ken