Anomic

Member

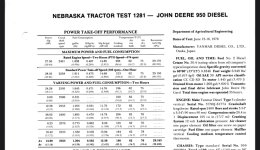

I currently own a John Deere 950 for background. I’ve been researching some about the 25hp “limit” where there is a large price jump to go up in power.

3025d 18,000$

3035d 22,600$

I’m having a hard time finding bare engine prices but looking at zero turns that have the same unit with different engine options for example

scag turf tiger 72” 25hp Kubota 23,999

Scag tiger 72” 40hp vanguard 18799

loose numbers a 40hp gas is 5k less than 25hp diesel which is 4.5k less than 35hp diesel. the gas would need to be water cooled in a CUT application but a hypothetical John Deere 3040D (gas) could come in under 14,000

I’m curious what y’all think. I know operating zero turns a 40hp gas can do a lot more than a 25hp diesel but how would it do for CUT application? I used Deere for this example but it may be even more beneficial for the budget brands to widen the price gap be the name brands while beating performance of the 25hp machines.

I love my diesel but using different zero turns I can not imagine paying 5k more for a 25hp diesel vs 40hp gas and most would agree. I wonder if that same logic applies to the CUT

3025d 18,000$

3035d 22,600$

I’m having a hard time finding bare engine prices but looking at zero turns that have the same unit with different engine options for example

scag turf tiger 72” 25hp Kubota 23,999

Scag tiger 72” 40hp vanguard 18799

loose numbers a 40hp gas is 5k less than 25hp diesel which is 4.5k less than 35hp diesel. the gas would need to be water cooled in a CUT application but a hypothetical John Deere 3040D (gas) could come in under 14,000

I’m curious what y’all think. I know operating zero turns a 40hp gas can do a lot more than a 25hp diesel but how would it do for CUT application? I used Deere for this example but it may be even more beneficial for the budget brands to widen the price gap be the name brands while beating performance of the 25hp machines.

I love my diesel but using different zero turns I can not imagine paying 5k more for a 25hp diesel vs 40hp gas and most would agree. I wonder if that same logic applies to the CUT