I have preached this 'til I'm blue in the face and yet nobody seems to listen. Last time.

1) The fuel injection pump and governor share a common oil sump. The only things that get lubricated by this oil are the camshaft lobes that lift the individual plungers, the eccentric cam that operates the lift pump push rod, rotating governor parts, and the rack. Since engine oil provides the highest shear strength between the cam lobes and plungers, it is the oil recommended by most manufacturers. Additives, if you will, are a waste of money here and provide no real advantage since there is no combustion taking place here, hopefully.

2) There is no direct mechanical connection between the fuel rack and the throttle rod bell crank except for the no fuel (stop) position. When you move the throttle without the engine running (governor turning) you are forcing the speeder spring against the flyweights in order to move the rack, and you will get very little movement at that because the buffer spring will prevent it. It's not a carbureted engine with a float bowl full of fuel - pumping the throttle does absolutely nothing except put abnormal wear and tear on the governor.

3) If you have a sticking rack it is probably caused by a seized or seizing barrel and plunger assembly (the individual high pressure fuel pumps). This symptom is almost always caused by dirty or contaminated fuel (water, diesel bugs). They are not sold separately. Keep your fuel as clean and fresh as possible

4) If you have fuel in your fuel injection pump oil (cross contamination) you have a leaking barrel and plunger assembly. There are no seals to replace, they are lap fitted and lubricated by fuel oil (a sulfur additive to the fuel is highly desirable).

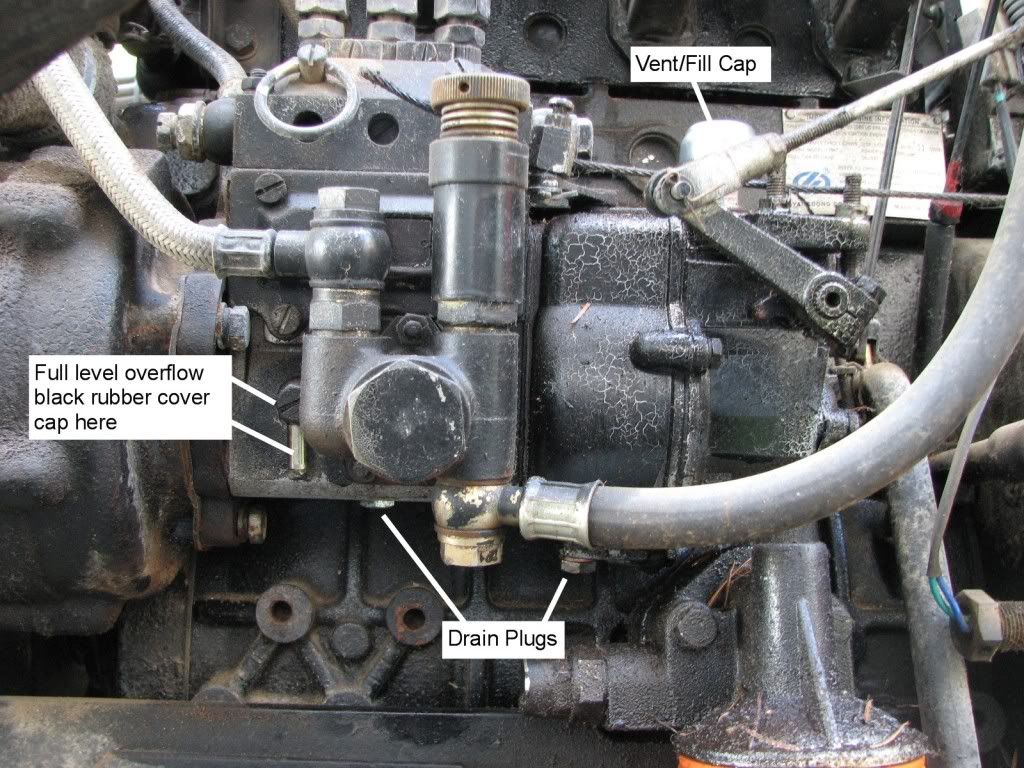

Here is a cutaway of a Bosch inline injection pump All the Chinese pumps are very similar, if not identical.

Diesel Injection Pump Cut-Away, with Inline 4 and Pneumatic Governor, Bosch - NADA Scientific