JPardue

New member

In 2020 bought a used NorTrac NT254 (Jinma 254) 25 HP 4x4 tractor with a power beyond loader valve.

Converted the welded bucket to skid steer quick attach and got a set of forks.

Wanted to add front remotes for a grapple.

Studying the hydraulics and looking online, it took some doing to figure out how to do this well.

My acres are far from a hydraulic shop, so 1st was building a hydraulic hose crimper for Eaton weatherhead crimping dies.

20 ton air/hydraulic jack provides crimping pressure.

Ebay for used crimping dies made it a bargain.

First hydraulic project: front remotes for a grapple.

This has worked out great, making it a workhorse for maintaining the property.

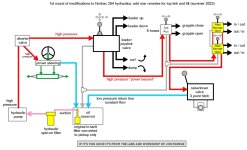

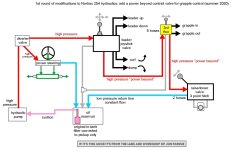

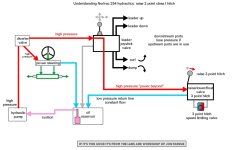

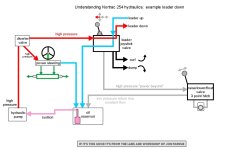

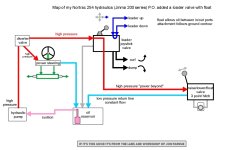

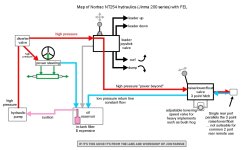

In an effort to grasp how the hydraulics function and to save on fittings, illustrating the system seemed like a good investment of time.

Respectfully my efforts may be wrong and incorrect to a hydraulics professional, but they explain it enough to help me.

Attached are some of the resulting diagrams.

Other diagrams have hose information, sizes and types of fittings used.

Everything is Pioneer quick disconnect, JIC and SAE O-ring boss without using any adapters.

Summer 2023:

Adding dual rear remotes for top link and tilt cylinders.

Shortening and rerouting some of the FEL hoses.

Converting to a spin-on hydraulic filter.

Adding more lights, doing maintenance and repairs is part of the process.

Repairing things poorly "fixed" before I bought it.

Perhaps the diagrams created might be useful or helpful to others.

This forum has been helpful to me, trying to post something of use in return.

Converted the welded bucket to skid steer quick attach and got a set of forks.

Wanted to add front remotes for a grapple.

Studying the hydraulics and looking online, it took some doing to figure out how to do this well.

My acres are far from a hydraulic shop, so 1st was building a hydraulic hose crimper for Eaton weatherhead crimping dies.

20 ton air/hydraulic jack provides crimping pressure.

Ebay for used crimping dies made it a bargain.

First hydraulic project: front remotes for a grapple.

This has worked out great, making it a workhorse for maintaining the property.

In an effort to grasp how the hydraulics function and to save on fittings, illustrating the system seemed like a good investment of time.

Respectfully my efforts may be wrong and incorrect to a hydraulics professional, but they explain it enough to help me.

Attached are some of the resulting diagrams.

Other diagrams have hose information, sizes and types of fittings used.

Everything is Pioneer quick disconnect, JIC and SAE O-ring boss without using any adapters.

Summer 2023:

Adding dual rear remotes for top link and tilt cylinders.

Shortening and rerouting some of the FEL hoses.

Converting to a spin-on hydraulic filter.

Adding more lights, doing maintenance and repairs is part of the process.

Repairing things poorly "fixed" before I bought it.

Perhaps the diagrams created might be useful or helpful to others.

This forum has been helpful to me, trying to post something of use in return.

Attachments

-

DIY hydraulic hose crimper.jpg248.6 KB · Views: 290

DIY hydraulic hose crimper.jpg248.6 KB · Views: 290 -

3rd function hydraulic + rear remotes.JPG187.3 KB · Views: 242

3rd function hydraulic + rear remotes.JPG187.3 KB · Views: 242 -

front remotes 3rd function hydraulic basic diagram.JPG167.5 KB · Views: 305

front remotes 3rd function hydraulic basic diagram.JPG167.5 KB · Views: 305 -

3PH lower diagram.jpg135.5 KB · Views: 237

3PH lower diagram.jpg135.5 KB · Views: 237 -

3PH raise diagram.jpg144.3 KB · Views: 216

3PH raise diagram.jpg144.3 KB · Views: 216 -

FEL loader down diagram.JPG126.1 KB · Views: 220

FEL loader down diagram.JPG126.1 KB · Views: 220 -

FEL loader up diagram.JPG153.1 KB · Views: 341

FEL loader up diagram.JPG153.1 KB · Views: 341 -

NT254 hydraulic diagram. with FEL float valveJPG.jpg147.2 KB · Views: 229

NT254 hydraulic diagram. with FEL float valveJPG.jpg147.2 KB · Views: 229 -

NT254 hydraulic basic diagram.JPG164.2 KB · Views: 396

NT254 hydraulic basic diagram.JPG164.2 KB · Views: 396