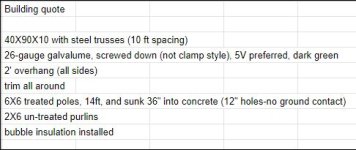

You seem to be leaning more toward having a contractor do it, but I know how these things go. You might bounce back and forth a few times before pulling a trigger. Let me just give a few tips I learned while building my pole barn.

1. Treated Wood poles are delivered moist. As they dry out, they twist/bend/warp to whatever degree they are allowed to. If you concrete them into the ground, leave them free-standing and come back a month later to install the roof, you'll find that your (hand-picked, straight-as-an-arrow) poles have bent, sometimes to a bafflingly extreme degree, and the tops are now off by as much as a foot or more. And they might have twisted as much as 10-20 degrees from bottom to top. Don't bring home your poles until you're ready to build them into some kind of structure that will keep them straight upright and aligned. If I had it to do over again, I would probably build wall sections laying on the ground and then lift the walls up and drop into the holes, then pour cement.

2. Building a pole barn all by yourself, especially if you've never done anything like it, is very time-intensive. If your time is worth anything at all, it probably makes more sense to pay someone with a crew and machinery to do the job. This was the hardest thing for me to swallow. I set out alone to save money and found that it just wasn't worth it. If I were retired with nothing better to do it would be a different story. I did get the job done, but not at any measurable savings.

3. 29ga material should be considered consumable. Use it to build your storage shed for dog food or something, but not for anything you expect to last. 26ga is the thinnest you should consider.

4. Welding steel lattice trusses is NOT a time or money saving venture. I was so proud of the truss design I made myself in CAD. I had my chest puffed out as I spent $500 in steel to build them. After 12 hours I had one of them 75% welded up. I had to throw in the towel. I absorbed that $500 loss (plus the $1,200 worth of lost time) and went out and bought the $900 worth of trusses I should have started with. That potential $400 savings turned into a $1,700 lesson; I hope to pass the savings on to you.

5. 2x4 wood purlins spanning 10ft is a recipe for disaster. I have 2x4 steel purlins spanning 8ft on 48" centers and I think I'm on the ragged edge of what you can get away with. This is an area with no snow, but high wind.

6. Speaking of wind, not sure what your area is like. Hurricanes? Tornadoes? If you experience any kind of high winds, ever, design around the assumption that there's a giant in the sky who wants to rip the roof off your structure as soon as you're done building it (or during construction). Trusses should be through-bolted to poles. Poles should be not merely cemented into the ground, but anchored into the cement. As cement cools/warms it shrinks/expands. It can shrink away from a wood pole to the point that the wood pole can be lifted out of the cement by hand. I drilled several beefy lag screws into the bottoms of my poles on all sides before cementing into the holes. Walls provide bracing against wind. Since you won't have walls (at least at first) you won't have that bracing. Using 6x6 will help but that giant in the sky is pretty determined. Mine doesn't have walls on all sides either, and I used tensioned wire rope cross-cabling on the sides to add wind resistance. Also in the roof. Nothing that could potentially experience any wind forces should be fastened with nails (IMHO); I used deck screws for everything. Using nails just invites the giant to a buffet of carnage.

7. The edges of the steel roof panels are very weak until they're fastened to something (like the next roof panel). As you're installing the roof, Dont step or put your weight anywhere near the unfastened/unsupported edge of the panel. It will buckle and deliver you to the ground with haste. You'll have injured yourself and wasted a panel. It's easy to forget this, especially when positioning and fastening the next panel. You look down and dont see an unsupported/ unfastened edge; you see 3 more feet of real estate. Until you get those two panels screwed together, what you're actually looking at is a strip of death zone.