eCRX

Bronze Member

- Joined

- May 25, 2016

- Messages

- 76

- Location

- Ayr

- Tractor

- 2004 Massey Ferguson GC2300, 2015 Cub Cadet XT2

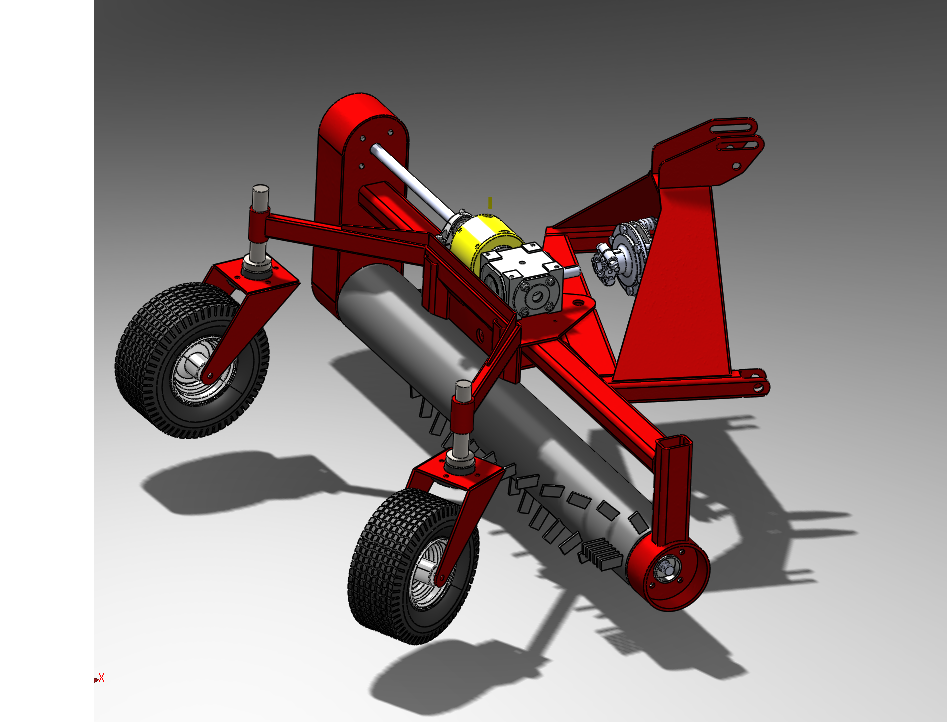

I started designing\modeling a power rake over the winter. (Got frustrated with sketchup so I purchased a student version of solidworks.)

A couple weeks ago I started the build.

It will be used by a GC2300 (22.5hp) and my brother-in-laws 26hp (L2650?) Kubota

some info:

most recent pic (drawn in solidworks)

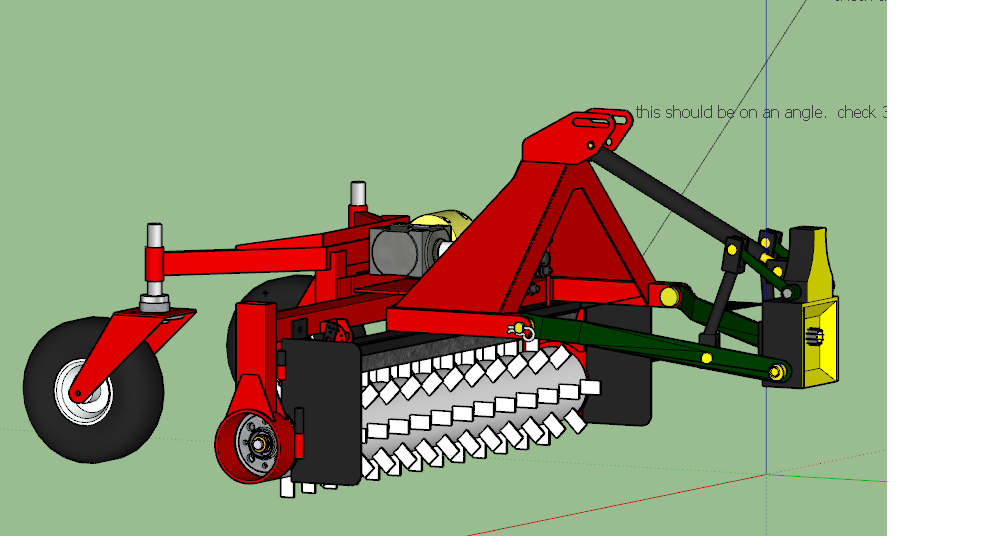

older Sketchup pic showing some additional aperture\side-shield details not yet drawn in my SW model. Barrowed a 3PH model from the sketchup library and scaled it to proper specs.

so far I machined the 1/4" 'disks' that go inside of sch40 pipe and did some threading for the spinny part.

chain sprocket 'weld hub'.

Will show more details when I mill the keyways. (hopefully this goes smooth as this will be my first time milling a keyway on a shaft! )

)

Will have more updates periodically.

A couple weeks ago I started the build.

It will be used by a GC2300 (22.5hp) and my brother-in-laws 26hp (L2650?) Kubota

some info:

- 54" x 6" sch40 main weapon

- Teeth - 1/4in AR400, tooth pattern/rake designed for lower hp (will be used on a GC2300 22.5hp and my brother-in-laws ?26hp? Kubota)

- Adjustable\Floating "Roll" on guide wheel assembly

- automotive rear wheel (thrust) bearing used on coast-side (typical flange bearing in chain case)

- removable 1-3/8 keyed shaft

- using 6" sch 40 for parts of the frame\chainbox.

most recent pic (drawn in solidworks)

older Sketchup pic showing some additional aperture\side-shield details not yet drawn in my SW model. Barrowed a 3PH model from the sketchup library and scaled it to proper specs.

so far I machined the 1/4" 'disks' that go inside of sch40 pipe and did some threading for the spinny part.

chain sprocket 'weld hub'.

Will show more details when I mill the keyways. (hopefully this goes smooth as this will be my first time milling a keyway on a shaft!

Will have more updates periodically.