etavarez

New member

- Joined

- Oct 17, 2010

- Messages

- 1

- Tractor

- John Deere 5420/ 521 Loader, Massey Ferguson 50

WOW Jim

Great modifications! a couple of questions:

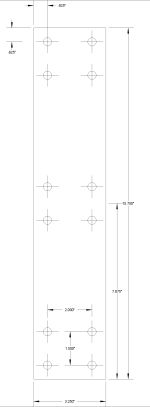

1. Did you have to remove the cylinder to make these mods? Since I can't see what the hydrolic connector configuration is under the unit, its tough to picture how you reversed the controls and hoses without having a bunch of extra hose under the unit.

2. It is difficult to tell what you are showing in your 2nd pic. It looks like a U-bracket bolted to the bottom on the back of the unit, but it isn't there in the other 2 pics?? just wondering what this is?

I'm planning on buying the 20 ton 3pt powerhorse to run off of my John Deere 5420. I have dual pumps that produce 15-16 GPM. What kind of cycle time do you think I can expect with this flow rate?

Again, you did a beautiful job on your modificaitons. I'm not as proficient with a welder as that yet but this is a great project to practice on.

Thanks

Eli

Great modifications! a couple of questions:

1. Did you have to remove the cylinder to make these mods? Since I can't see what the hydrolic connector configuration is under the unit, its tough to picture how you reversed the controls and hoses without having a bunch of extra hose under the unit.

2. It is difficult to tell what you are showing in your 2nd pic. It looks like a U-bracket bolted to the bottom on the back of the unit, but it isn't there in the other 2 pics?? just wondering what this is?

I'm planning on buying the 20 ton 3pt powerhorse to run off of my John Deere 5420. I have dual pumps that produce 15-16 GPM. What kind of cycle time do you think I can expect with this flow rate?

Again, you did a beautiful job on your modificaitons. I'm not as proficient with a welder as that yet but this is a great project to practice on.

Thanks

Eli