OP

boggen

Elite Member

- Joined

- Feb 22, 2011

- Messages

- 3,789

- Location

- Trivoli, IL

- Tractor

- SSTT (Sideways Snake Tain Tractor) and STB (sideways train box) tractor, dirt harvester

what about a regular old, fan blade from some car or truck. placed on a pully that then connects to pto shaft?

not sure how i would build a circular area around the blades though. perhaps 2 sheets of plywood with a circle cut out in the center. with some 2x4's or 2x6's between the plywood. and the fan blade sets in the middle of it all. with some wire mesh on both sides. so no fingers or body parts get mangled.

hhhmmsss be nice to have a hydraulic motor, as i think about it. that could just spin at wanted RPMs and turn a fan blade. other words instead of an electrical motor. it would be an hydraulic motor.

just a simple box with fan and hyd motor. with the case around the fan. that would allow easy connection to a piece of plywood with some screws. piece of plywood being part of a container.

hhmmsss what about a old push motor, poping off the gas motor, and installing a hydraulic motor. and some how fastening the mower deck to a container?

*scratches his head* the tractors i have, and i assuming most other tractors more so without cabs, or extra work lights, don't have the battery capacity nor the alternator capacity, to run a 12v to 110v converter to run a couple shop vac motors.

===============

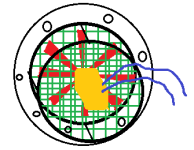

picture = fan encased in a generic circular housing, with a face plat that you can either use screws, or bolts to mount to a container. with some grills on both sides, to keep unwanted body parts out of it. along with a direct drive hyd motor setting outside of grills, and hoping motor only needs power to one side, and other line is a gravity return line. if hyd hoses reversed. the fan would become a blower.

not sure how i would build a circular area around the blades though. perhaps 2 sheets of plywood with a circle cut out in the center. with some 2x4's or 2x6's between the plywood. and the fan blade sets in the middle of it all. with some wire mesh on both sides. so no fingers or body parts get mangled.

hhhmmsss be nice to have a hydraulic motor, as i think about it. that could just spin at wanted RPMs and turn a fan blade. other words instead of an electrical motor. it would be an hydraulic motor.

just a simple box with fan and hyd motor. with the case around the fan. that would allow easy connection to a piece of plywood with some screws. piece of plywood being part of a container.

hhmmsss what about a old push motor, poping off the gas motor, and installing a hydraulic motor. and some how fastening the mower deck to a container?

*scratches his head* the tractors i have, and i assuming most other tractors more so without cabs, or extra work lights, don't have the battery capacity nor the alternator capacity, to run a 12v to 110v converter to run a couple shop vac motors.

===============

picture = fan encased in a generic circular housing, with a face plat that you can either use screws, or bolts to mount to a container. with some grills on both sides, to keep unwanted body parts out of it. along with a direct drive hyd motor setting outside of grills, and hoping motor only needs power to one side, and other line is a gravity return line. if hyd hoses reversed. the fan would become a blower.