Rowski

Veteran Member

- Joined

- May 18, 2000

- Messages

- 1,474

- Location

- North Central Vermont, Jay Peak Area

- Tractor

- 2004 New Holland TN70DA with 32LC loader, 2000 New Holland 2120 with Curtis cab, 7309 loader

Here's a stupid question.

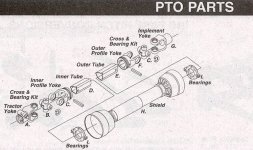

Is the PTO shaft protective shielding supposed to rotate with the shaft or are the chains suppose to keep it from rotating with the shaft?

This is for my Valby chipper, not that it matters. The only info I find in the owners manual (and the warning stickers on the chipper) say the cover NEEDS to rotate freely. If the shaft "spins freely with the pto shaft" what is the function of the chains on the cover. Only thing I can figure is to keep the to shaft from comimg apart when unhooking one end of the shaft.

Thanks.

Derek

Is the PTO shaft protective shielding supposed to rotate with the shaft or are the chains suppose to keep it from rotating with the shaft?

This is for my Valby chipper, not that it matters. The only info I find in the owners manual (and the warning stickers on the chipper) say the cover NEEDS to rotate freely. If the shaft "spins freely with the pto shaft" what is the function of the chains on the cover. Only thing I can figure is to keep the to shaft from comimg apart when unhooking one end of the shaft.

Thanks.

Derek