RNeumann

Elite Member

How did you run the hydraulic winch?

How did you run the hydraulic winch?

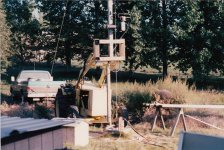

Off the rear remotes on the tractor. I looked for a picture I have of it set up pulling the pump, but I can't find it.

Also if you are having to pull a pump every couple of years, something is not right. Knowing how to make sure you get proper cooling flow past the motor and how to keep the pump from cycling can make the difference between 2 and 20 years of pump life.

My neighbor had weird things happen with his well. Once the little nut that holds the check valve in place in the pump came off, so we had to pull it out. Should have dinged up the threads a little to lock it on. Another time the pump shaft twisted off when it started. He was careful not to let it cycle very often. It would run continuously while he was irrigating. He was just very unlucky with that well.

Thanks for all the good info from your experience. You have to be careful and think about what you're doing.