WinterDeere

Super Star Member

- Joined

- Sep 6, 2011

- Messages

- 13,654

- Location

- Rural 'burbs, north of Philly

- Tractor

- John Deere 3033R, 855 MFWD, 757 ZTrak; IH Cub Cadet 123

Here's one for all you draftsmen and pattern makers out there. Yeah, I mean you, @dadohead, @dodge man, @wawajake, and @Grumpycat... among others.

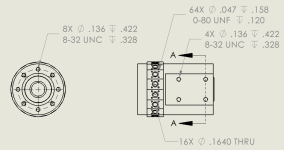

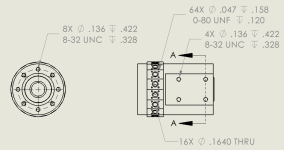

I need to indicate the clocking of a circular hole pattern on the end of a cylinder, relative to a radial hole pattern on the cylindrical face. Or put otherwise, in the attached drawing snippet, I need to indicate the clocking tolerance of the 8x Ø.136 drill pattern in the view on the left, to the clocking orientation of the 16x Ø.1640 THRU holes in the view on the right. I assume I snap a datum on one and use a location tolerance on the other, but not having ever properly learned GDT (I'm EE, not ME), I'm not sure the best way to properly note this.

I intend to specify the tolerance in degrees rotation, not inches displacement.

Thanks!

I need to indicate the clocking of a circular hole pattern on the end of a cylinder, relative to a radial hole pattern on the cylindrical face. Or put otherwise, in the attached drawing snippet, I need to indicate the clocking tolerance of the 8x Ø.136 drill pattern in the view on the left, to the clocking orientation of the 16x Ø.1640 THRU holes in the view on the right. I assume I snap a datum on one and use a location tolerance on the other, but not having ever properly learned GDT (I'm EE, not ME), I'm not sure the best way to properly note this.

I intend to specify the tolerance in degrees rotation, not inches displacement.

Thanks!