HCJtractor

Veteran Member

- Joined

- Jan 28, 2009

- Messages

- 1,519

- Location

- upstate South Carolina, Greenville

- Tractor

- Kubota M6800, Massey Ferguson 240

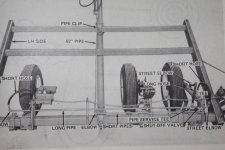

I am building a cultipacker and want it to be transportable. I have the wheel assemblies that were taken off an old Allis Chalmers planter that i converted to a three point hitch style, so I plant to make this packer in the same manner that the planter was designed, using left over parts for the wheels and frames. I would love to be able to drive the hydraulics without using my tractor hydraulics. My question is could this system be driven by a manual pump or a 12 V pump as it is designed? I am showing you the diagram from the manual that show the system, of which I have all the parts. If not, I need to modify it someway so that I can use a manual pump and a ram, or a ratchet jack. My main frame will be similar to the one in the diagram except with only two cross members, not three. And only two wheels (the third wheel in the diagram is for a fertilizer drive which is not part of the wheel assembly). Total weight will be around 1000 lbs, some of which will be supported by the tongue.

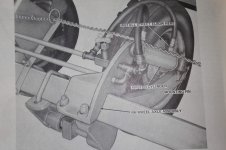

Note the old system uses a 3" x 8" double action cylinder and a 2" x 8" single action slave cylinder. Is there a way to use a pump other than the tractor remotes that would not be too expensive? I don't mind having to spend a minute or so pumping as this will not be something I have to lift a lot. Those of you who know hydraulics and want a "farmer engineered" challenge, please take a look and offer your thoughts.

Ignore the chain and middle wheel as that is not there. There are only two identical wheel assemblies. The one on the right is the master and the one on the left is the slave. Its really a pretty simple design, but I am making it complicated by not wanting to have to use my tractor. So my question is simply this: what other ways can this system as designed be powered??

Note the old system uses a 3" x 8" double action cylinder and a 2" x 8" single action slave cylinder. Is there a way to use a pump other than the tractor remotes that would not be too expensive? I don't mind having to spend a minute or so pumping as this will not be something I have to lift a lot. Those of you who know hydraulics and want a "farmer engineered" challenge, please take a look and offer your thoughts.

Ignore the chain and middle wheel as that is not there. There are only two identical wheel assemblies. The one on the right is the master and the one on the left is the slave. Its really a pretty simple design, but I am making it complicated by not wanting to have to use my tractor. So my question is simply this: what other ways can this system as designed be powered??