gerard

Veteran Member

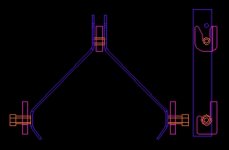

I also have a landpride quick hitch purchased form Carvers and I know it was a lot less thaan $325 even with shipping. Closer to $200 if memory serves......... My adjustable top link hook adjusts with two small pins with cotter clips through them so it adjusts really easily. No tools, pull two pins, move up/down, replace pins, and put back cotters. (Not actually cotter pins but I don't know what they're called - maybe spring pins??) I also can leave it in the same poisition for everything but the box blade. For that I drop it down because I use the bolt holding the two angles together as the top link attachment point. The Landpride also comes with two pieces of flat stock with two holes drilled in each end. If you're implement has metal in the way so the quickhitch hook can't fit, you use the two plates and it "extends" the top link pins so you don't have to modify any implements. (Should have taken some pics, would have been a lot clearer)