Hello All and especially Larry G.,

Well, I found out I do have a ball valve, just like you said Larry, and I was able to get it turned 1/4 turn clockwise and it began draining. I did all the things you said to Larry and it turned out good, mine was not too bad though, it appears it had anti-freeze in it already and was fairly clear, thank goodness, but the radiator cap was really bad, so it was replaced with the part number you gave me and NAPA had them in stock.

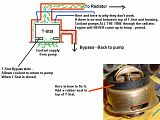

Do you think I will need to look at my Thermosstat? or do you think it should be O.k.? The tractor always seems to run very cool, even in the Summer here in Southern Cal.

Thanks again all for the great help

Rick

Well, I found out I do have a ball valve, just like you said Larry, and I was able to get it turned 1/4 turn clockwise and it began draining. I did all the things you said to Larry and it turned out good, mine was not too bad though, it appears it had anti-freeze in it already and was fairly clear, thank goodness, but the radiator cap was really bad, so it was replaced with the part number you gave me and NAPA had them in stock.

Do you think I will need to look at my Thermosstat? or do you think it should be O.k.? The tractor always seems to run very cool, even in the Summer here in Southern Cal.

Thanks again all for the great help

Rick