You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rear Counter Weight

- Thread starter esz

- Start date

- Views: 13661

More options

Who Replied?

/ Rear Counter Weight

#1

Branson Bob

Platinum Member

Anyone know where to find the recommended amount of rear counter weight when using a FEL? I checked the tractor & loader manual, but found nothing.

Good question.

As you know, the "ideal" weight is a compromise because the material in the FEL varies in weight. Most of the compact utility tractors (CUTs) have a 1/2 yard bucket... about 13 cubic feet. A 1/2 yard of topsoil (depending on moisture) is about 800 lbs. A 1/2 yard of crushed stone is about twice that.

I always have something on the back of the tractor, either the backhoe or an attachment but I don't have a ballast box yet.

The other guys will correct me but I think somewhere around 800-900 lbs would be a good starting weight. This ballast box has a capacity of 800 lbs:

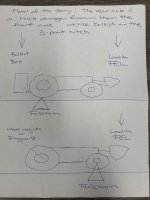

Also, keep in mind the principal below:

Attachments

bindian

Super Member

I am gonna guess about half the weight of what your loader is rated to lift. My loader is rated for 3900 pounds. My backhoe weighs around 1800 pounds and my 8 foot land plane with a 900 pound Red Oak cant on it weighs around 1700 pounds. Even these on occasion are still not enough to keep the rear tires deep in the dirt when moving huge logs.

hugs, Brandi

hugs, Brandi

bindian

Super Member

If your drawing is correct, please tell me why my butt gets lite and my front tires go flat when I try to lift a too heavy load with the loader. The fulcrum would be on the front axle with a loader.

hugs, Brandi

ning

Elite Member

The loader weight has the fulcrum at the front tires, yes. Increased load increases weight on the front axle and because of the lever effect it reduces load on the rear (making the butt lighter).If your drawing is correct, please tell me why my butt gets lite and my front tires go flat when I try to lift a too heavy load with the loader. The fulcrum would be on the front axle with a loader.

hugs, Brandi

A counterweight has its fulcrum at the rear tires - unless the rear tires are in the air in which case it's at the front tires. Increased load here increases weight on the rear axle and reduces load on the front.

How much balast has to do with the maximum load the front axle - which is the weakest link in the system - can handle.

For a yourself tractor that weighs 5000 with loader but no cargo, and 1500# on the front axle and 3500# on the rear, and let's say the front axle max is 2500#.

If you put 1000# in the loader you're likely to overload the front axle because the load is levered out in front of it, which means that the center of mass of the entire tractor+load system is now farther forward - the rear is getting lighter and some of the previously rear weight is now being carried by the front axle in addition to that cargo weight.

This is why you need a counterweight. Filled tires aren't enough; they just make it harder to get the rear up, but they don't keep the front from getting overloaded because the weight isn't behind the rear axle (it's directly over it) so it can't reduce the front axle load.

By using a counterweight, which has its fulcrum at the rear tires, you move the center of mass rearwards and the rear axle ends up carrying more.

How much counterweight? The math is complex: it depends on

- how much cargo

- geometry of the tractor

- tractor wheelbase

- distance from the cargo to the front axle

- distance from the center of mass of the counterweight to the fulcrum (rear tires contact)

The same weight a foot farther back will balance more weight.

Ideally I suspect you want the counterweight to perfectly balance out the cargo in the loader. To make life easier though, people probably try to balance off an average to heavy load.

Best would be to have a scale; weigh at the front axle without load, then with a heavy load with counterweight, and add weight until you get back to the unloaded weight on the front - or at least a value comfortably under the axle max load.

oosik

Epic Contributor

I have 1550# of Rim Guard in the rear tires and a 1050# rear blade on the 3-point. I know my Kubota M6040 will lift more than 3000# but limit lifts to around 2800# max. Why - safety. How - I have two charts. One that tells me the weight of basaltic lava rocks - the other the weight of green pine tree trunks. You can find these charts on the internet.

K5lwq

Elite Member

- Joined

- Aug 6, 2017

- Messages

- 4,918

- Location

- Mineola, TX

- Tractor

- Kioti LK2554, Branson 4815C, Satoh Beaver, Speedex

One thing I do is always use 2WD when lifting heavy loads. If the tractor will not move because the back tire is spinning, I know I need more counterbalance. Using 4WD to overcome the rear tire slipping is a bad idea. With that much weight in the bucket plus the weight of the tractor is way more than the front drive train is designed to handle. Also remember low and slow when transporting a heavy load on the loader.

Torvy

Super Member

Not sure which CUTs you mean. The 20 series has a 9.5 cu. ft. bucket. The 494/574 has 11.3 cu. ft. bucket. Those are pretty big CUTs. The 35 series is not any bigger than the 20. The 454/554 do have a 13.8. I couldn't find info on the bigger CUT/Utility (654/754). The 1104 has a 19+ bucket, but it is a Utility, not CUT.Good question.

As you know, the "ideal" weight is a compromise because the material in the FEL varies in weight. Most of the compact utility tractors (CUTs) have a 1/2 yard bucket... about 13 cubic feet. A 1/2 yard of topsoil (depending on moisture) is about 800 lbs. A 1/2 yard of crushed stone is about twice that.

I always have something on the back of the tractor, either the backhoe or an attachment but I don't have a ballast box yet.

The other guys will correct me but I think somewhere around 800-900 lbs would be a good starting weight. This ballast box has a capacity of 800 lbs:

Also, keep in mind the principal below:

Attachments

Slowpoke Slim

Elite Member

- Joined

- Jan 6, 2017

- Messages

- 3,916

- Location

- Bismarck, ND

- Tractor

- Husqvarna YTH24V48 riding mower, Branson 3725CH

I would say as a general rule of thumb, I would carry at least half of your rear 3-pt rated weight as a good ballast. Now if your rear tires are filled (mine are filled with Rimguard-highly recommend), then maybe a bit less than half rear 3 pt capacity. I can lift anything up to max rating (2000 lbs) with a 900 lb blower on the rear (filled rear tires).

And the old legacy Branson 20 series is the same size as the 25 series. The 35 series was larger, and the 45 series was larger still.

And the old legacy Branson 20 series is the same size as the 25 series. The 35 series was larger, and the 45 series was larger still.

Torvy

Super Member

If that was to me, I was just talking about the bucket. The data is on the website. The 35 series is still being made, not past tense.And the old legacy Branson 20 series is the same size as the 25 series. The 35 series was larger, and the 45 series was larger still.

esz

Member

- Joined

- Nov 25, 2015

- Messages

- 26

- Location

- Colorado

- Tractor

- Kubota L2550DT Kubota BX2200D Branson 2515H

Thanks for all the info. My bucket max lift is 2200 lb, volume 8 cu ft (I will seldom max it out and, in any case, not sure what material weighs 2200# for 8 cu ft), 3 pt capacity 3300 lb. I just ordered a ballast box that will weigh about 800 after I fill it with concrete. That is probably a good starting point and more than I have on my Kubota which just has a 200 lb blade on the back; so I don't lift very big loads. Yes, my Kubota rear tires got light at times, so it will be nice to have more weight.

Thanks again.

Thanks again.

Last edited:

notaz3

Gold Member

- Joined

- Feb 17, 2020

- Messages

- 483

- Location

- Here for summer, there in winter.

- Tractor

- 2022 Kubota L3560HSTC

Torvy

Super Member

I think for many people it is not how much you lift in your bucket, it would be with forks or a grapple.Thanks for all the info. My bucket max lift is 2200 lb, volume 8 cu ft (I will seldom max it out and, in any case, not sure what material weighs 2200# for 8 cu ft), 3 pt capacity 3300 lb. I just ordered a ballast box that will weigh about 800 after I fill it with concrete. That is probably a good starting point and more than I have on my Kubota which just has a 200 lb blade on the back; so I don't lift very big loads. Yes, my Kubota rear tires got light at times, so it will be nice to have more weight.

Thanks again.

kantuckid

Platinum Member

I have that one but never weighed it. I filled mine with crushed rock and store my logging chains on top the rock where it's settled in. I keep my drawbars and a spudbar in the holes mades into my box corners and at times a shovel/rake, etc.. I also have a ball hitch used for hay wagon pulling and at times i'll loop a chain over that ball for light pulls. Like many things steel and shipped, they've gone up by quantum leaps in price.Good question.

As you know, the "ideal" weight is a compromise because the material in the FEL varies in weight. Most of the compact utility tractors (CUTs) have a 1/2 yard bucket... about 13 cubic feet. A 1/2 yard of topsoil (depending on moisture) is about 800 lbs. A 1/2 yard of crushed stone is about twice that.

I always have something on the back of the tractor, either the backhoe or an attachment but I don't have a ballast box yet.

The other guys will correct me but I think somewhere around 800-900 lbs would be a good starting weight. This ballast box has a capacity of 800 lbs:

Also, keep in mind the principal below:

Attachments

dj1701

Veteran Member

I never thought much about the mathematics of the situation. I just throw a suitable size implement on the back and go lift s**t.

Dave

Dave

ning

Elite Member

Just remember that the closer the ballast is to the rear axle, the less it counterweights (to unload the front axle).Thanks for all the info. My bucket max lift is 2200 lb, volume 8 cu ft (I will seldom max it out and, in any case, not sure what material weighs 2200# for 8 cu ft), 3 pt capacity 3300 lb. I just ordered a ballast box that will weigh about 800 after I fill it with concrete. That is probably a good starting point and more than I have on my Kubota which just has a 200 lb blade on the back; so I don't lift very big loads. Yes, my Kubota rear tires got light at times, so it will be nice to have more weight.

Thanks again.

Someday I'm going to build a ballast box setup that's adjustable, so the same weight can be moved farther back to lever better. The reason to make it adjustable in position is of course the farther back it is, the more it's a liability to hit things or just be in the way (like the backhoe).

Branson Bob

Platinum Member

If your drawing is correct, please tell me why my butt gets lite and my front tires go flat when I try to lift a too heavy load with the loader. The fulcrum would be on the front axle with a loader.

hugs, Brandi

I'm not sure I can explain it much clearer. As in the Messick's video if the rear wheels are off the ground the front axle is obviously the fulcrum. Conversely, when the front wheels are off the ground (as they are when I'm carrying a boulder using my pallet forks on my 3 point hitch) then the rear axle is the fulcrum. (In this situation I use my split brakes to steer the tractor.)

If I have my backhoe on and my FEL bucket off, the front end is very light and prone to bouncing if I'm driving fast enough on bumpy ground. This indicates (by degrees) that the rear axle is the fulcrum.

What you're trying to accomplish with counterweight/ballast behind/aft of the the rear axle is to reduce the amount of weight on the front axle which is prone to failure when overloaded.

I might add there's a misconception that adding weight to the rear wheels (wheel weights or Rimguard) reduces the weight on the front axle. This is not true because that weight is not behind/aft of the rear axle. Such weight will counterweight the load in the FEL but it doesn't shift the fulcrum to the rear axle.

I hope this makes a bit more sense.

4570Man

Super Star Member

- Joined

- Apr 7, 2015

- Messages

- 19,011

- Location

- Crossville, TN

- Tractor

- Kubota M59, Kubota L3800, Grasshopper 428D, Topkick dump truck, 3500 dump truck, 10 ton trailer, more lighter trailers.

I'm not sure I can explain it much clearer. As in the Messick's video if the rear wheels are off the ground the front axle is obviously the fulcrum. Conversely, when the front wheels are off the ground (as they are when I'm carrying a boulder using my pallet forks on my 3 point hitch) then the rear axle is the fulcrum. (In this situation I use my split brakes to steer the tractor.)

If I have my backhoe on and my FEL bucket off, the front end is very light and prone to bouncing if I'm driving fast enough on bumpy ground. This indicates (by degrees) that the rear axle is the fulcrum.

What you're trying to accomplish with counterweight/ballast behind/aft of the the rear axle is to reduce the amount of weight on the front axle which is prone to failure when overloaded.

I might add there's a misconception that adding weight to the rear wheels (wheel weights or Rimguard) reduces the weight on the front axle. This is not true because that weight is not behind/aft of the rear axle. Such weight will counterweight the load in the FEL but it doesn't shift the fulcrum to the rear axle.

I hope this makes a bit more sense.

Counter weight does save the front axel but not in the way most people think. It would take immense counter weight to actually lighten the front axel by a lot. 800 pounds on a 4000 pound tractor isn’t even close to reaching that point. But what the counter weight does do is increase the traction on the rear tires. The front axel ring gears aren’t that strong and weren’t designed to do all the work. If the back tires are more planted and doing most of the work the front axel will be better off.

bindian

Super Member

The OP was asking about counterweight on the rear for loads in the loader bucket. Your drawing shows the fulcrum on the rear axle. I was nicely trying to tell you your fulcrum is on the wrong axle for this discussion.I'm not sure I can explain it much clearer. As in the Messick's video if the rear wheels are off the ground the front axle is obviously the fulcrum. Conversely, when the front wheels are off the ground (as they are when I'm carrying a boulder using my pallet forks on my 3 point hitch) then the rear axle is the fulcrum. (In this situation I use my split brakes to steer the tractor.)

If I have my backhoe on and my FEL bucket off, the front end is very light and prone to bouncing if I'm driving fast enough on bumpy ground. This indicates (by degrees) that the rear axle is the fulcrum.

What you're trying to accomplish with counterweight/ballast behind/aft of the the rear axle is to reduce the amount of weight on the front axle which is prone to failure when overloaded.

I might add there's a misconception that adding weight to the rear wheels (wheel weights or Rimguard) reduces the weight on the front axle. This is not true because that weight is not behind/aft of the rear axle. Such weight will counterweight the load in the FEL but it doesn't shift the fulcrum to the rear axle.

I hope this makes a bit more sense.

I do know a thing about weight and balance. It was required in my work as an aircraft mechanic of 42 years.

Brandi