Wedge,

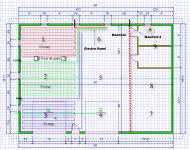

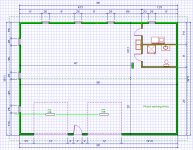

Let's be sure we are talking the same language here. I define a loop as one run of tubing from the manifold and back. A zone is an area controlled by a thermostat. It can have any number of loops. Some rooms might have more than one loop, but the loops should be set up to only heat one area. In other words, a given loop only heats one room, but runs of tube, to and from that room, can travel through common areas. That's the way you show yours and that is good. then you can balance the flow to adjust the heating level in all the various areas. Bedrooms can be cooler than kitchens and warmer than storage rooms, etc. If you use 1/2" PEX make your maximum length 300'. 3/4" can be 500' max. Or mix and match for different areas. A bathroom might have 1/2" tube on 6" centers with 150 linear feet, and a shop might have 3/4" tube on 12" centers with 400 linear feet. Try to make all loops about the same length if practical, or near the same restriction with different diameters. If you have a small room with a 150' loop, do the larger rooms with (2) 150' loops, etc. Once you get this more or less worked out you will know what manifold to get. A manifold with one more set of outlets than you plan is a good thing because you can add one more loop or make a short crossover from out to in for stabilizing the flow and temp.

No need to run the tubing under any cabinets. Keep it 10" or more in front of the toilet pipe, no need to go behind it. Don't put it under the refrigerator. Closets are optional. Pantries are optional. Be sure to put it where your feet will be in any office spaces or work stations near machinery. Be sure it is in pathways. Run the tubing into and out of each room by going through the door, if possible. This frees you up to drill under floor plates and it makes a warm path through the door for walking.

Try to arrange the bar or the tube so you can run the tube along with the upper bar.

Hold the heat back about 1' from the inside of exterior walls.

Near exterior doors you can make an extra pass at 6" and you should also keep the spacing closer in the bathroom.

Route your supply line along the outside wall first and then make your runs across the room that came back and "touch" the feed line as they do their U bend. See it in my pictures.

You can run your sup and ret lines to a given room side by side, or siamese them, as you pass through a common area to get to your destination room. The siamesed lines can run on 12" centers with other paired lines.

Pass the PEX through PVC conduit 90s to enter and exit the slab. 3/4" for 1/2" PEX and 1" for 3/4" PEX.

You seem to show two manifolds. Why?