You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Replacing fuel line?

- Thread starter bkline19

- Start date

- Views: 2775

More options

Who Replied?

/ Replacing fuel line?

#1

RustyA

Platinum Member

Use same diameter brake line? Remove your line and take to auto parts store to match up length? If you don't have tubing cutter and flaring tools some stores will shape and finish a line for you?

i7win7

Elite Member

remove it, an auto parts store can sell you all the needed parts

rScotty

Super Member

- Joined

- Apr 21, 2001

- Messages

- 9,831

- Location

- Rural mountains - Colorado

- Tractor

- Kubota M59, JD530, JD310SG. Restoring Yanmar YM165D

Can anyone advise how to go about replacing this fuel line on a Jinma 284? I'm not too mechanically inclined so I could benefit from pretty explicit feedback!

Thanks in advance

I'm not familiar with Jinma, but I'm guessing you cannot simply order one from them or you would do that....

One problem I have with changing what you have is we we don't know what that connection to the fuel tank really looks like. We know what it resembles....from what we can see it looks like it is probably an inverted flare nut holding a flared connection to the fuel tank. That wouldn't be simple if it were a standard US imperial standard thread, and is complicated because what you have is probably to some metric standard. Or even to a manufacturer's own standard.

There are several different threads and types of flare that it could be. It could be a compression collar or a formed flare. It can be a single or double flare. For a flare to work, it has to be exact, surgically clean, symmetrical, and it has to match the existing flare in the fuel tank exactly. Add to that the probability that it is made to a metric flare standard and now it is unlikely to be a flare you will automatically find at your local auto parts store. There there are many flares and flare threads, all different....and we don't know which one you have.

If you have a local hydraulic shop, you might take that photo you posted to them and see if they have an idea. But if they do, they will want the old fuel line in hand before they do anything.

I've got a simple idea that might work. It involves hoping that both ends of the fuel line are identical, and if so then we keep the existing flare and metal tube on both ends, but replace that poor quality central rubber portion. Removing the old rubber and then sliding a better quality rubber or silicone fuel line over the metal tube and securing the replacement with a pair of small hose clamps on each end. For this to have any chance of working, the other end where the fuel line screws into the fuel filter needs to look pretty close to being like the end in your photo.

So since you said you wanted explicit feedback, step 1 is to take a picture of the other end of the fuel line and post it here.

While you are doing that photo take notice if the fuel line gets exposed to a engine heat in normal operation, how long it is, and approximently how far the other end is below the tank end. (Vertical distance).

BTW, we are concerned about vertical distance because the fuel line should always be decending as it travels between the fuel tank and the fuel filter. Otherwise it can trap an air bubble and shut off the flow.

Good luck,

rScotty

WranglerX

Super Member

Agree with rScotty..... Just cut off and replace cracked rubber portion if both ends have enough steel tube to clamp to...And for clamps use quality Fuel Injection style, lot better than "worm" style clamps...

Super helpful - I'll get some photos asap to help diagnose further!I'm not familiar with Jinma, but I'm guessing you cannot simply order one from them or you would do that....

One problem I have with changing what you have is we we don't know what that connection to the fuel tank really looks like. We know what it resembles....from what we can see it looks like it is probably an inverted flare nut holding a flared connection to the fuel tank. That wouldn't be simple if it were a standard US imperial standard thread, and is complicated because what you have is probably to some metric standard. Or even to a manufacturer's own standard.

There are several different threads and types of flare that it could be. It could be a compression collar or a formed flare. It can be a single or double flare. For a flare to work, it has to be exact, surgically clean, symmetrical, and it has to match the existing flare in the fuel tank exactly. Add to that the probability that it is made to a metric flare standard and now it is unlikely to be a flare you will automatically find at your local auto parts store. There there are many flares and flare threads, all different....and we don't know which one you have.

If you have a local hydraulic shop, you might take that photo you posted to them and see if they have an idea. But if they do, they will want the old fuel line in hand before they do anything.

I've got a simple idea that might work. It involves hoping that both ends of the fuel line are identical, and if so then we keep the existing flare and metal tube on both ends, but replace that poor quality central rubber portion. Removing the old rubber and then sliding a better quality rubber or silicone fuel line over the metal tube and securing the replacement with a pair of small hose clamps on each end. For this to have any chance of working, the other end where the fuel line screws into the fuel filter needs to look pretty close to being like the end in your photo.

So since you said you wanted explicit feedback, step 1 is to take a picture of the other end of the fuel line and post it here.

While you are doing that photo take notice if the fuel line gets exposed to a engine heat in normal operation, how long it is, and approximently how far the other end is below the tank end. (Vertical distance).

BTW, we are concerned about vertical distance because the fuel line should always be decending as it travels between the fuel tank and the fuel filter. Otherwise it can trap an air bubble and shut off the flow.

Good luck,

rScotty

Thank you for the suggestion!Agree with rScotty..... Just cut off and replace cracked rubber portion if both ends have enough steel tube to clamp to...And for clamps use quality Fuel Injection style, lot better than "worm" style clamps...

View attachment 722246

Super helpful - I'll get some photos asap to help diagnose further!

And just to clarify, the new rubber portion will have to be a larger diameter if we're intending it to go OVER the top of the existing tube, correct? In other words, the rubber line will now serve as the "female" and the metal tube will become the "male" ... am I following correctly?I'm not familiar with Jinma, but I'm guessing you cannot simply order one from them or you would do that....

One problem I have with changing what you have is we we don't know what that connection to the fuel tank really looks like. We know what it resembles....from what we can see it looks like it is probably an inverted flare nut holding a flared connection to the fuel tank. That wouldn't be simple if it were a standard US imperial standard thread, and is complicated because what you have is probably to some metric standard. Or even to a manufacturer's own standard.

There are several different threads and types of flare that it could be. It could be a compression collar or a formed flare. It can be a single or double flare. For a flare to work, it has to be exact, surgically clean, symmetrical, and it has to match the existing flare in the fuel tank exactly. Add to that the probability that it is made to a metric flare standard and now it is unlikely to be a flare you will automatically find at your local auto parts store. There there are many flares and flare threads, all different....and we don't know which one you have.

If you have a local hydraulic shop, you might take that photo you posted to them and see if they have an idea. But if they do, they will want the old fuel line in hand before they do anything.

I've got a simple idea that might work. It involves hoping that both ends of the fuel line are identical, and if so then we keep the existing flare and metal tube on both ends, but replace that poor quality central rubber portion. Removing the old rubber and then sliding a better quality rubber or silicone fuel line over the metal tube and securing the replacement with a pair of small hose clamps on each end. For this to have any chance of working, the other end where the fuel line screws into the fuel filter needs to look pretty close to being like the end in your photo.

So since you said you wanted explicit feedback, step 1 is to take a picture of the other end of the fuel line and post it here.

While you are doing that photo take notice if the fuel line gets exposed to a engine heat in normal operation, how long it is, and approximently how far the other end is below the tank end. (Vertical distance).

BTW, we are concerned about vertical distance because the fuel line should always be decending as it travels between the fuel tank and the fuel filter. Otherwise it can trap an air bubble and shut off the flow.

Good luck,

rScotty

Fuddy1952

Elite Member

- Joined

- Apr 17, 2018

- Messages

- 4,332

- Location

- South Central Virginia

- Tractor

- 1973 Economy and 2018 John Deere 3038E

Sounds stupid I guess but it looks easy. I'd have an extinguisher at hand and rubber plugs ready once removed to plug hole.

Then line off should be easy to match size...as mentioned a steel line should work fine, (tubing) bent to fit.

Then line off should be easy to match size...as mentioned a steel line should work fine, (tubing) bent to fit.

rScotty

Super Member

- Joined

- Apr 21, 2001

- Messages

- 9,831

- Location

- Rural mountains - Colorado

- Tractor

- Kubota M59, JD530, JD310SG. Restoring Yanmar YM165D

And just to clarify, the new rubber portion will have to be a larger diameter if we're intending it to go OVER the top of the existing tube, correct? In other words, the rubber line will now serve as the "female" and the metal tube will become the "male" ... am I following correctly?

Yes, that's the way I see it. The fuel line would slip over the metal tube. It might require cutting the metal tube. If so, I'd say to use a tubing cutter or very fine tooth jeweler's saw. You want to preserve the metal tubes.

So next is what kind of rubber fuel line to use. The rubber hose is not just to carry the fluid, it serves to isolate the rigid tank from the vibrating engine. There are a lot of types of rubber fuel lines in the market right now - and I don't have a clear feeling for which would stand up the best. For my own work I've been using some medium heavy rubber fuel line I got from a guy who services Honda Generators. It is holding up well, but I have no idea what it is made of. I'd say - guessing - that what I'm using has less wall thickness than what I see in that photo in message #1. Just get good quality fuel line and inspect it is what I do.

On clamps, I usually use two per end & confess to using worm drive clamps all too often.

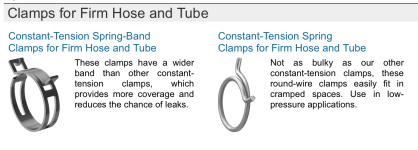

The world of clamps is divided into those that follow the expansion and contraction of the rubber as it ages....and those that do not. Worm drive and most bolted types do not follow dimensional changes well. Spring clamps of the "constant tension" type do.

But really for low pressure gravity feed systems as long as the fuel line hose material remains elastic either type will do. It's when the fuel line gets old that you get leaks with them all.

luck,

rScotty

Here is a picture from McMaster.com

Last edited:

rScotty

Super Member

- Joined

- Apr 21, 2001

- Messages

- 9,831

- Location

- Rural mountains - Colorado

- Tractor

- Kubota M59, JD530, JD310SG. Restoring Yanmar YM165D

Not a problem. That would make it a return line to the fuel tank rather than a feed line to the fuel filter. It's more complex now because there are several lines, but it is still a low pressure line filled with fuel that has leaky age cracks in the rubber.

There should also be a hard steel line to each injector. See if you can get a picture of the complete injector - best to do them all.

Also, we originally assumed that the upper right hand side in your first photo was a connection into the wall of the fuel tank, but we ought to confirm that.

rScotty

There should also be a hard steel line to each injector. See if you can get a picture of the complete injector - best to do them all.

Also, we originally assumed that the upper right hand side in your first photo was a connection into the wall of the fuel tank, but we ought to confirm that.

rScotty

RustyA

Platinum Member

Hard to tell for sure with wiring loom over fitting in the picture but it almost looks like a banjo style fitting on the engine side?

Yes - the original picture was in fact a connection into the wall of the fuel tank. In this last photo it's a bit blurry but that's the same connection point.Not a problem. That would make it a return line to the fuel tank rather than a feed line to the fuel filter. It's more complex now because there are several lines, but it is still a low pressure line filled with fuel that has leaky age cracks in the rubber.

There should also be a hard steel line to each injector. See if you can get a picture of the complete injector - best to do them all.

Also, we originally assumed that the upper right hand side in your first photo was a connection into the wall of the fuel tank, but we ought to confirm that.

rScotty

Yes - the original picture was in fact a connection into the wall of the fuel tank. In this last photo it's a bit blurry but that's the same connection point.

Yes I believe it's the same style fitting as what is up at the fuel tank as well. I couldn't get a reasonable photo today since the sun wasn't shining out here in the northeast!Hard to tell for sure with wiring loom over fitting in the picture but it almost looks like a banjo style fitting on the engine side?