You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Rtv servo issues

- Thread starter Steve rtv

- Start date

- Views: 21289

More options

Who Replied?

/ Rtv servo issues

#11

SpudHauler

Gold Member

Before you do, just check that the rear brakes are completely returning.

Others have reported brakes stuck on reducing speeds to 10-15mph.

The pivots get packed with mud, don't return properly and stay on.

With the rear jacked up, make sure you can turn each wheel by hand when the cam lever is all the way back. Possibly unhook cables and check for full movement on both sides.

Remove the debris and hopefully this helps.

Worth checking.

Others have reported brakes stuck on reducing speeds to 10-15mph.

The pivots get packed with mud, don't return properly and stay on.

With the rear jacked up, make sure you can turn each wheel by hand when the cam lever is all the way back. Possibly unhook cables and check for full movement on both sides.

Remove the debris and hopefully this helps.

Worth checking.

timswi

Super Member

- Joined

- Nov 18, 2008

- Messages

- 5,301

- Location

- Beaver County Pa

- Tractor

- Kubota BX23 TLB, Kubota RTV1100, Kubota Z724 & Polaris RZR 900 Trail

def not the brakes ,

what is behind the servo adjustment bolt when i tighten it seems to bottom out frighted of going any more seems as if some thing is stuck or broke

I forget the direction of adjustment as it's been a couple of years but too far one way and the machine won't move..Incrimentally the other way and the performance can be slightly adjusted to a point of diminishing returns.

Has anyone messed with that adjustment in the recent past?

timswi

Super Member

- Joined

- Nov 18, 2008

- Messages

- 5,301

- Location

- Beaver County Pa

- Tractor

- Kubota BX23 TLB, Kubota RTV1100, Kubota Z724 & Polaris RZR 900 Trail

def not the brakes ,

what is behind the servo adjustment bolt when i tighten it seems to bottom out frighted of going any more seems as if some thing is stuck or broke

Here's my explaination of the servo adjustment for an RTV500 from a few years ago..Doubt it differs much for a 900 (ignore the RPM adjustment)..Can't be sure though:

You get to the screw by lifting the bed...There is a rectangular black bok that is just under the seat. If you look to the front of that, there is a stud sticking out, with a slot in the end. It is held in place by a 14mm jambnut. Loosen the jambnut and back out the stud one turn at a time. Make sure you re-tighten the jamb nut after each adjustment. Don't get carried away.

Remember that these are underpowered to begin with, so all we are trying to do is sqeeze everything we can out of it.

When you test drive, make sure you are at full operating temperature or you won't be able to tell if it helped or not.

After you get it where you want it, you may want to check the max RPMS as well. mine and many others were set to 3600...The update is to go to 4000.

Well put gauges on the two ports adjacent to the HST filter both read 100 psi , There is a third port higher up but not accessible as behind a welded chassis part . We investigated under the top plate were the piston will slide back and forth adjacent to servo have proved that it will only drive in reverse piston only moves one direction so thinking seal in servo or on one end of the piston housing . this housing is filled with oil when engine is started so assume charge pump to be intact .

I would welcome any opinions .

Thank you Steve

I would welcome any opinions .

Thank you Steve

SpudHauler

Gold Member

Steve,

Do you have a manual?

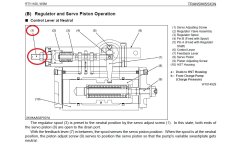

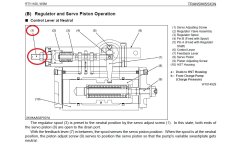

My knowledge of the servo screw, is this;

If you have adjusted it and now don't know were it is set at, then turn it in until it reaches bottom, back the screw out 1 1/2 turns. The range is 0 to 3 turns, with 1 1/2 being the middle. From this point you never go any further than 1/2 turn inward or outward from the middle position. In other words, from bottom it's 1-2 turns.

Should the plunger inside stick and not move out after adjusting to 1 1/2 turns, it may take a little drive to get the pressure up to move it out. Hopefully you can tell by lightly moving the screw out and back in by 1/4 turn to see if you can feel resistance. Either way leave it set a 1 1/2 turns. Otherwise you have to remove the servo body and free up the little plunger. Hard to see in the second diagram but the adjusting bolt pushes on that little plunger inside and it is positioned by the spring inside of it. You can just barely see a little gap between it and the servo body, that's the range of adjustment.

Adjusting on this screw has the least effect of all adjustments to the HST. So leave it until last and only move it by 1/8 of a turn either way to see if you get any improvements.

The neutral screw and HST rod adjustments are key to getting smoother shifting.

Anyone who has never adjusted there servo screw should make careful notes of it's factory position so they can return to that location if they make adjustments that don't work.

View attachment rtv900servo.bmp

Do you have a manual?

My knowledge of the servo screw, is this;

If you have adjusted it and now don't know were it is set at, then turn it in until it reaches bottom, back the screw out 1 1/2 turns. The range is 0 to 3 turns, with 1 1/2 being the middle. From this point you never go any further than 1/2 turn inward or outward from the middle position. In other words, from bottom it's 1-2 turns.

Should the plunger inside stick and not move out after adjusting to 1 1/2 turns, it may take a little drive to get the pressure up to move it out. Hopefully you can tell by lightly moving the screw out and back in by 1/4 turn to see if you can feel resistance. Either way leave it set a 1 1/2 turns. Otherwise you have to remove the servo body and free up the little plunger. Hard to see in the second diagram but the adjusting bolt pushes on that little plunger inside and it is positioned by the spring inside of it. You can just barely see a little gap between it and the servo body, that's the range of adjustment.

Adjusting on this screw has the least effect of all adjustments to the HST. So leave it until last and only move it by 1/8 of a turn either way to see if you get any improvements.

The neutral screw and HST rod adjustments are key to getting smoother shifting.

Anyone who has never adjusted there servo screw should make careful notes of it's factory position so they can return to that location if they make adjustments that don't work.

View attachment rtv900servo.bmp

No awaiting manual , we have been fiddling a bit today along the lines of the neutral adjustment as per your recommendations , and we now seem to have a machine that operates ,have not tried under load yet and it still does not answer why it would suddenly change from being great to awfull in one trip around the wood . We fiddled with it for a few hours and then it was if an air blockage or something that was stuck just came back . We got it going forward which was a great improvement from reverse only ! But it had no power then after changing gear and giving it some revs it just seemed to work .

I do understand the servo srew and the neutral adjuster now as I have had them apart . I will post more tomorrow when it comes back from my workshop at work and I get chance to test fully .

Thank you for you input gentlemen

Ta Steve

I do understand the servo srew and the neutral adjuster now as I have had them apart . I will post more tomorrow when it comes back from my workshop at work and I get chance to test fully .

Thank you for you input gentlemen

Ta Steve

Similar threads

- Replies

- 0

- Views

- 1K

- Replies

- 3

- Views

- 1K