Hello everyone,

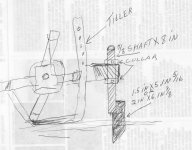

I picked up a used bcs 720 w/ a 20in tiller. The tines were completely worn down and wouldn't bite into the ground at all so I just installed a replacement set. Now it's actually biting into the ground but I'm having issues of it basically popping a wheel and running away on the tines instead of the wheels.

I was wondering if that was a common issue with really compacted soil or if I installed the new tillers wrong.

Thanks,

-Tom

I picked up a used bcs 720 w/ a 20in tiller. The tines were completely worn down and wouldn't bite into the ground at all so I just installed a replacement set. Now it's actually biting into the ground but I'm having issues of it basically popping a wheel and running away on the tines instead of the wheels.

I was wondering if that was a common issue with really compacted soil or if I installed the new tillers wrong.

Thanks,

-Tom