arto98607

Veteran Member

- Joined

- Aug 27, 2014

- Messages

- 1,300

- Location

- Southwest WA

- Tractor

- Kubota F3060, Grasshopper 721D, Ford 1310, John Deere 440 ICD, John Deere 300

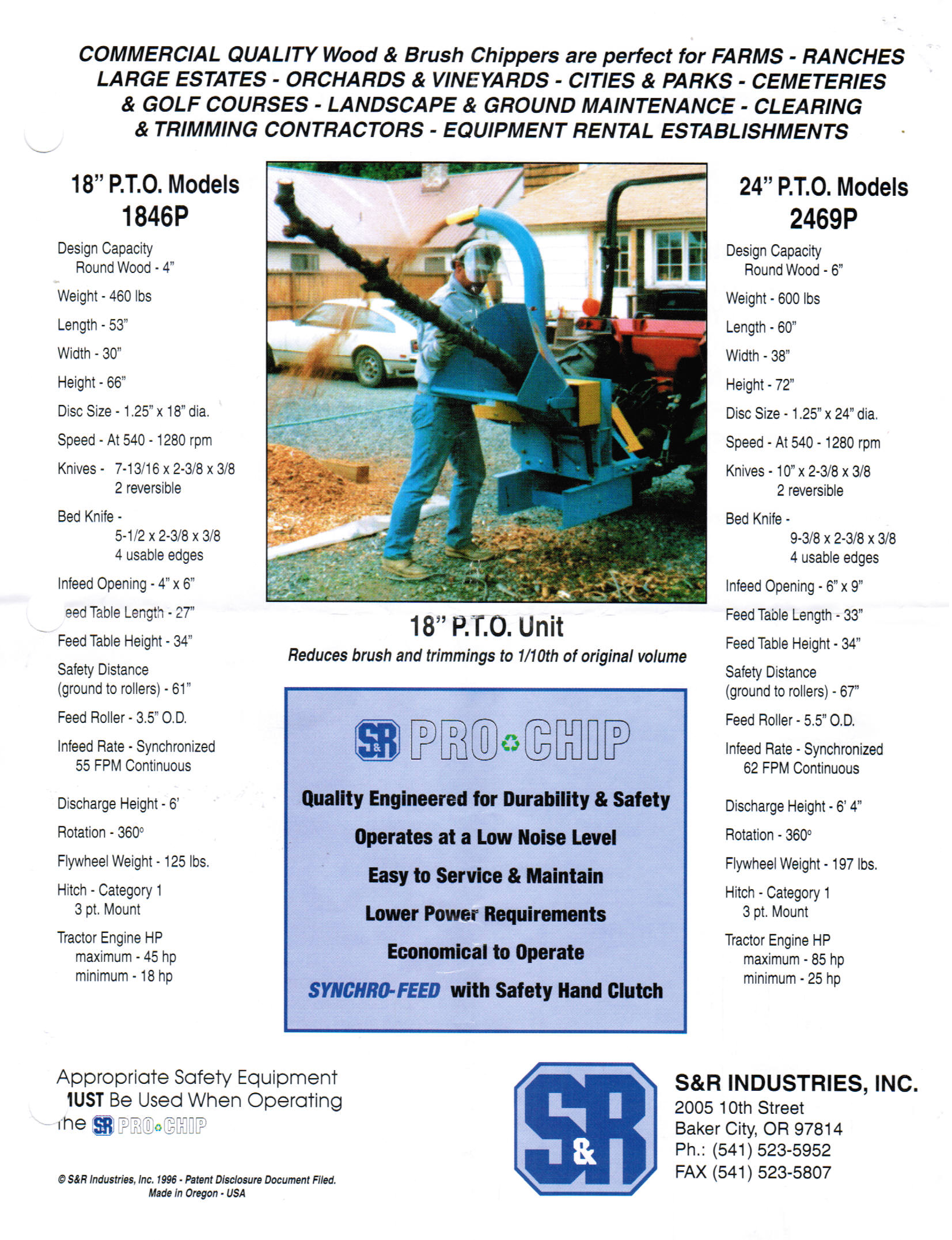

I bought this S&R chipper used back in 1998 and have been delaying knife sharpening for couple of years, due to reluctance of shipping them out to someone not having previously dealt with.

Earlier this month I located what looks like very competent sharpening shop close-by and so far am very happy of the work they did!

Changing the knives in S&R Pro Chip is really not very hard to do, after you remove the inlet chute and swing the feed roller out of the way. There is also easy to remove access plate on the PTO side.

Sharp knives made a huge difference on how easily & steady the feed roller is able to feed in fir branches. It is also noticeable how much less engine power is required - my Ford 1310 has only 19 hp engine!

Normally anything over around 2.5 inches diameter is used for firewood.

Obviously a modern new chipper with hydraulic driven feeder & clam-shell design would be nice to have, but as long as the knives are reasonably sharp this will do fine!

Also this chipper is a good mach for this tractor, due to the belt drive input shaft height matching the PTO height in my tractor (about 15 inches off the ground).

IE. Some of the new chippers I have looked at have their input shaft at about 22 inches off the ground which would not be as suitable.

Earlier this month I located what looks like very competent sharpening shop close-by and so far am very happy of the work they did!

Changing the knives in S&R Pro Chip is really not very hard to do, after you remove the inlet chute and swing the feed roller out of the way. There is also easy to remove access plate on the PTO side.

Sharp knives made a huge difference on how easily & steady the feed roller is able to feed in fir branches. It is also noticeable how much less engine power is required - my Ford 1310 has only 19 hp engine!

Normally anything over around 2.5 inches diameter is used for firewood.

Obviously a modern new chipper with hydraulic driven feeder & clam-shell design would be nice to have, but as long as the knives are reasonably sharp this will do fine!

Also this chipper is a good mach for this tractor, due to the belt drive input shaft height matching the PTO height in my tractor (about 15 inches off the ground).

IE. Some of the new chippers I have looked at have their input shaft at about 22 inches off the ground which would not be as suitable.