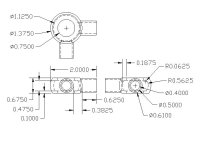

This is the latest variation of the Autocad drawing that I am loosely following. It has the dual port, and some additional dimensions that would not be needed for a CNC job, but when doing it by hand, it's handy to be able to measure how far a cut should go or something. I find it useful to have more dimensions than are actually necessary so I don't have to do any calculating at the bench that I might screw up.

/forums/images/graemlins/smirk.gif

/forums/images/graemlins/smirk.gif