I've been playing around with sheet metal lately. Way back, I first showed a trial of the fuel/oil tank. It was too straight. I wanted the top to have a little crown to it. Then the second tank I made, it was too short. I can't help it. I'm picky and I want things a certain way.

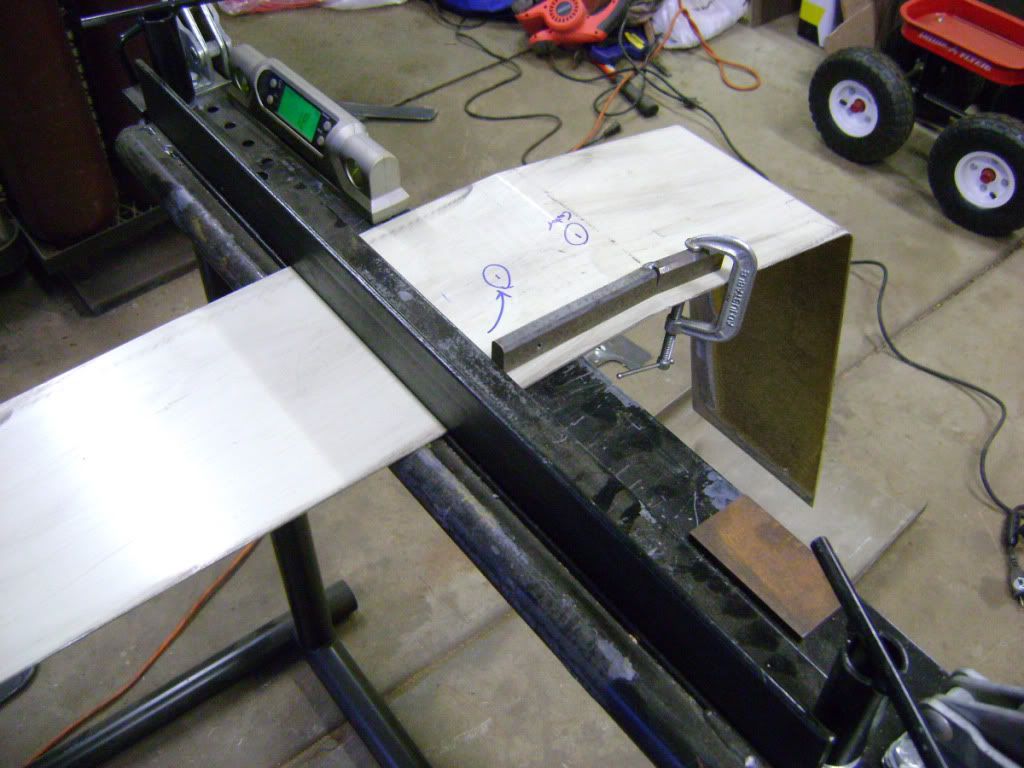

So this time, I used a digital angle finder and a little gauge. So I'd bend the center to 7 degrees then the outer edges (using the gauge to get the distance from the center even) to 68 degrees. If you notice that doesn't add up, it's because when I put the piece on the table between two clamped pieces of steel spaced 16 inches apart, I get a real nice, and consistent crown. It worked really well.

Here is the fuel/oil tank with one end welded on as well as the front grill surround.

When I laid them on top of each other, they matched up perfectly. I was very happy with they way they turned out this time. And when I mean this time, it wasn't without some failures before I used the angle finder and gauge. Good thing I have a bunch of scrap panels.

However, the next problem I ran into was the hood. I'm using 14 gauge sheet. It was free and nice and heavy duty. The tank was 7 inches wide and the grill is 4 inches wide. It bent fine. The hood....it's 19 inches long. And my bender just wasn't having any of that. I tried a few different things and it just wasn't working. And even if I got the bends, I still probably wouldn't be able to bow it to get that nice crown. I think I'm going to have to try something thinner. I'll go to Menards tomorrow to see if I can find a decent sheet of 18 gauge that I can try out.

As for the sprockets and idler wheels, I'm still waiting on the guy that's going to burn them out. He ordered a hi-def plasma cutter for his shop back in January. It's been delayed a few times but it's supposed to be in by June. I want it to be a nice cut and supposedly hi-def plasma cutters are close to laser. So I'm on hold until then.