CTyler

Veteran Member

I have a 50x64x12 Pole building that was insulated when built. The insulation is between the poles/wood and metal siding. This is a Cleary building, similar to Astro, Morten etc..

I have a problem with rain and snow in the winter time getting the insulation wet when its blowing. The top 2x4, not treated, also shows several places where is has gotten wet. There isn't any standing water or anything like that in the shop. However if its' not corrected it will start rotting the wood over time. Besides I want to cover the inside with drywall.

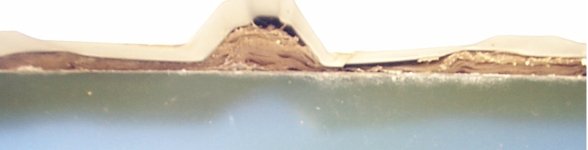

There is a small gap between the metal roofing and the siding that needs to get sealed up. What should I use to keep the moisture out? I'm not sure if a expanding foam would hold and or repel the water.

I need to look closely to see exactly how big the gap is up there. I'm guessing its to much gap to silicone.

I have a problem with rain and snow in the winter time getting the insulation wet when its blowing. The top 2x4, not treated, also shows several places where is has gotten wet. There isn't any standing water or anything like that in the shop. However if its' not corrected it will start rotting the wood over time. Besides I want to cover the inside with drywall.

There is a small gap between the metal roofing and the siding that needs to get sealed up. What should I use to keep the moisture out? I'm not sure if a expanding foam would hold and or repel the water.

I need to look closely to see exactly how big the gap is up there. I'm guessing its to much gap to silicone.