woodlandfarms said:

Barry, that Plum Crazy e-body is worth 150 to 250K on the market right now. That convertible could easily clear 400K... I LOVE the E Bodies. And the new Challenger is really well designed. Hate the new charger. There is a spread in Car and Driver featuring my car and the new Charger. Really no comparison.

The really funny thing is that you can tell most of the people who own the new Charger no nothing about cars or its history. I am always asked by them what my car is.... Then they look at theres and look at mine... There smile goes away..

Carl

Ya, I know I've seen the prices. I had always planned on keeping the convertible for that very reason. Never realized back then they would go for so much on the market today, or I may have had a little more incentive.

The new Challenger is going to be a beaut. I plan to get one when I can swing it. I would really love to do what your doing and buy a classic. Being honest with myself I know I couldn't afford to restore it right, and do it justice. So I'll go with the 2008 challenger.

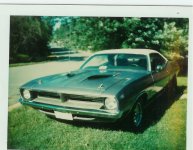

I know I'm telling my age when I talk about the 70's. Your right most people have no idea of Mopars history. I also owned some other Mopars which I won't bore anyone one else with. Here is my old 1958 party wagon if I remember the year right. I had a lot of fun in this old truck. It had the old flat head 6 and was bullet proof. One more of my Cuda, had a little rainbow thing going on in this one. So I always liked this picture.

I tell my son who is 20 about the old Mopars he doesn't have a clue. I had some friends back then that drove Road Runners, Super Bee's GTX's to many to list . One friend of mine had a nice, I think it was a 67 Charger. Not as nice looking as the 69's much boxer looking, still it was an exciting car to drive or ride in.

My all time favorite chase scene and Im sure would be yours is in the classic Bullitt, with Steve McQueen. Sweat running charger in that one. The other is Vanishing point, story line not as well done, but was nice watching the Challenger put through its paces.