BukitCase

Elite Member

- Joined

- Feb 17, 2012

- Messages

- 2,756

- Location

- Albany OR

- Tractor

- Case 580B, Long 460, Allis-Chalmers 160

"I suspect the container would be cooler inside if the roof were run to entirely cover the container top and then air could flow between the top of the container and the roof. And the sun would beat down on the roof instead of directly on the container top."

2Many, I can confirm your suspicions completely - I have 5 containers; a 20' standard, 2 40' standards and 2 40' Hi Cubes - The 20' is presently the ONLY one with a roof - roof is 24' x 24', which leaves about a 14' wide x 24' area BESIDE the container where my gantry crane, O/A welder and some storage shelves live - that is the ONLY container that (partly from a couple shade trees, but mostly the roof) is ALWAYS the same temperature as the outside air - I've never seen condensation or any other problem in that one in just over 10 years.

The two standard 40's are end to end, making an 80' long storage area 12' away from, and parallel to, my (mostly) wood shop - whenever the sun shines, those two (with unfettered southern exposure) need to have some sort of ventilation or they COOK whatever's inside them; presently this is done with exhaust fans hung just inside one of the doors, a royal PITA that I have greenhouse cooling systems in house (but yet to be installed) - once those are done (involves some plasma cutting and impenetrable inlet vents, plus the automatic exhaust fans)

The two 40' Hi cubes are side by side, and eventually will get a slab poured and relocated - looking at putting a 48'x60' pole structure over the whole thing, which will give about 30x60 enclosed space for working on the bigger equipment - 25' scissor lift, 50' boom lift, 2 tractors, backhoe, 6 yd dump truck, etc.

Without the fans on (20" commercial in each container) I've measured (60 degree day, slight breeze, full sun) as much as 150 degrees F inside ALL 4 using an IR temp gun. The fans drop it to around 100-110 degrees. The northern HiCube stays a little cooler because it's shaded by the southern one, which has full southern exposure on the south side.

Would I do it that way again? Maybe not exactly, but yeah; partly because I have a "neighbor" on one side that needs to be reminded from time to time that I really DO have a 12 gauge AND a backhoe, and am too old and cranky to think FIRST - I musta got the "Dirty Harry" character pretty close, 'cause in the last few years things've settled down over there noticeably

Pics or it didn't happen ... Steve

... Steve

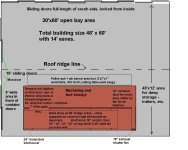

Oh, the roof frame is mostly .120 wall 2" tube with some 1/4" wall where needed, still gotta fab double doors for both ends and a wall (right side of pic for a drive-thru) - The entire roof is modular, eventually I want to put a 3 car garage with a partial second story that would just clear that gray triangle near the center - the open side is framed in 3 identical 8'x12' modules that are bolt together, so that side can be dismantled in 3 sections.

Also, the jacks are HF's 20 ton air/hydraulic, I used some 3/4x3 FB and made a couple of "sorta" toe jack conversions - I re-plumbed the air control a bit so I could have either one jack on each side or on each end, and control BOTH from wherever I needed to be to see what I was doing. Works OK, but I'd do the toe jack adapter a bit different next time...

2Many, I can confirm your suspicions completely - I have 5 containers; a 20' standard, 2 40' standards and 2 40' Hi Cubes - The 20' is presently the ONLY one with a roof - roof is 24' x 24', which leaves about a 14' wide x 24' area BESIDE the container where my gantry crane, O/A welder and some storage shelves live - that is the ONLY container that (partly from a couple shade trees, but mostly the roof) is ALWAYS the same temperature as the outside air - I've never seen condensation or any other problem in that one in just over 10 years.

The two standard 40's are end to end, making an 80' long storage area 12' away from, and parallel to, my (mostly) wood shop - whenever the sun shines, those two (with unfettered southern exposure) need to have some sort of ventilation or they COOK whatever's inside them; presently this is done with exhaust fans hung just inside one of the doors, a royal PITA that I have greenhouse cooling systems in house (but yet to be installed) - once those are done (involves some plasma cutting and impenetrable inlet vents, plus the automatic exhaust fans)

The two 40' Hi cubes are side by side, and eventually will get a slab poured and relocated - looking at putting a 48'x60' pole structure over the whole thing, which will give about 30x60 enclosed space for working on the bigger equipment - 25' scissor lift, 50' boom lift, 2 tractors, backhoe, 6 yd dump truck, etc.

Without the fans on (20" commercial in each container) I've measured (60 degree day, slight breeze, full sun) as much as 150 degrees F inside ALL 4 using an IR temp gun. The fans drop it to around 100-110 degrees. The northern HiCube stays a little cooler because it's shaded by the southern one, which has full southern exposure on the south side.

Would I do it that way again? Maybe not exactly, but yeah; partly because I have a "neighbor" on one side that needs to be reminded from time to time that I really DO have a 12 gauge AND a backhoe, and am too old and cranky to think FIRST - I musta got the "Dirty Harry" character pretty close, 'cause in the last few years things've settled down over there noticeably

Pics or it didn't happen

Oh, the roof frame is mostly .120 wall 2" tube with some 1/4" wall where needed, still gotta fab double doors for both ends and a wall (right side of pic for a drive-thru) - The entire roof is modular, eventually I want to put a 3 car garage with a partial second story that would just clear that gray triangle near the center - the open side is framed in 3 identical 8'x12' modules that are bolt together, so that side can be dismantled in 3 sections.

Also, the jacks are HF's 20 ton air/hydraulic, I used some 3/4x3 FB and made a couple of "sorta" toe jack conversions - I re-plumbed the air control a bit so I could have either one jack on each side or on each end, and control BOTH from wherever I needed to be to see what I was doing. Works OK, but I'd do the toe jack adapter a bit different next time...

Attachments

Last edited: