schmism

Super Member

Hears your chance.

Ive moved my shop 3 times now. each time to a slightly larger shop. (so im not new to setting up shop pun intentended) My past garage being a standard 2 car (20x22 or so) and is currently PACKED with tools.

With the recent property purches it came with a 32x60 x 12 (i think) pole barn. The point is its HUGE! i mean just F'n HUGE!

like im standing in it sat night with it lit with the 3 flourecent fixtures. (enough light to seee, but really not "work by" pondering were to put stuff... and i am faced with that problem of its SO large... i really dont know were to start.

so the layout/givens.

the south west corner

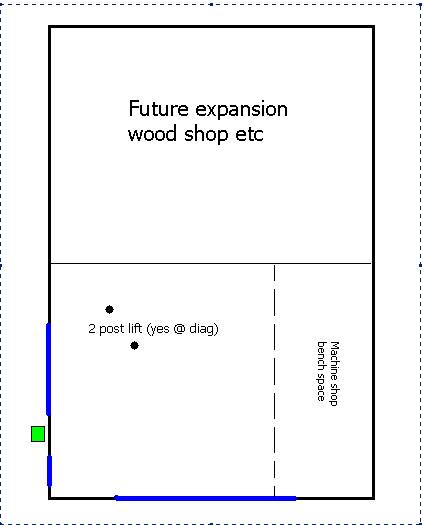

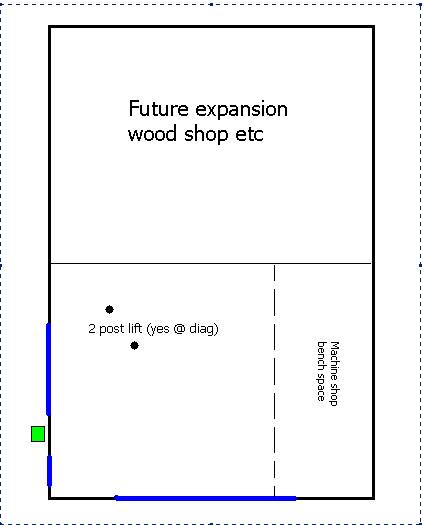

.jpg)

as you can see i have a large front "2 door" sliding entrance. full height, 20' probibly. to the left of the man door is a single sliding door probibly 16' wide.

gravel floor.

no other entrances.

What i have (will have)

full machine/fab/mechincs shop. Everything from rebuilding engines, to body work, off road fab, to oil changes. (i have a small personal fleet of cars/trucks)

addtionally i have a full woodworking shop. As you can imagine the 2 dont really work together well. machine work doesnt like dust, and wood doesnt like grease.

I WILL have a 2 post lift.

I really only want to put concreet in half for right now( $$ considerations)

considerations

I need space to park the tractor

I need space for 2 post lift

I have no other covered parking so a daily "garage" duities for 2 cars (till something else "garage" like is built)

Im considering converting the single sliding door to a 16' (or double 8') roll up doors. the rear most (most north of the 2) would have the lift located in it.

With this layout i could still have the front door as pull in access for reg maintaince or tractor parking. The east 10' used for bench and machine shop layout.

what say you?

FYI hears a quick sketch

Ive moved my shop 3 times now. each time to a slightly larger shop. (so im not new to setting up shop pun intentended) My past garage being a standard 2 car (20x22 or so) and is currently PACKED with tools.

With the recent property purches it came with a 32x60 x 12 (i think) pole barn. The point is its HUGE! i mean just F'n HUGE!

like im standing in it sat night with it lit with the 3 flourecent fixtures. (enough light to seee, but really not "work by" pondering were to put stuff... and i am faced with that problem of its SO large... i really dont know were to start.

so the layout/givens.

the south west corner

.jpg)

as you can see i have a large front "2 door" sliding entrance. full height, 20' probibly. to the left of the man door is a single sliding door probibly 16' wide.

gravel floor.

no other entrances.

What i have (will have)

full machine/fab/mechincs shop. Everything from rebuilding engines, to body work, off road fab, to oil changes. (i have a small personal fleet of cars/trucks)

addtionally i have a full woodworking shop. As you can imagine the 2 dont really work together well. machine work doesnt like dust, and wood doesnt like grease.

I WILL have a 2 post lift.

I really only want to put concreet in half for right now( $$ considerations)

considerations

I need space to park the tractor

I need space for 2 post lift

I have no other covered parking so a daily "garage" duities for 2 cars (till something else "garage" like is built)

Im considering converting the single sliding door to a 16' (or double 8') roll up doors. the rear most (most north of the 2) would have the lift located in it.

With this layout i could still have the front door as pull in access for reg maintaince or tractor parking. The east 10' used for bench and machine shop layout.

what say you?

FYI hears a quick sketch