blacksmith

Bronze Member

- Joined

- Jan 6, 2004

- Messages

- 66

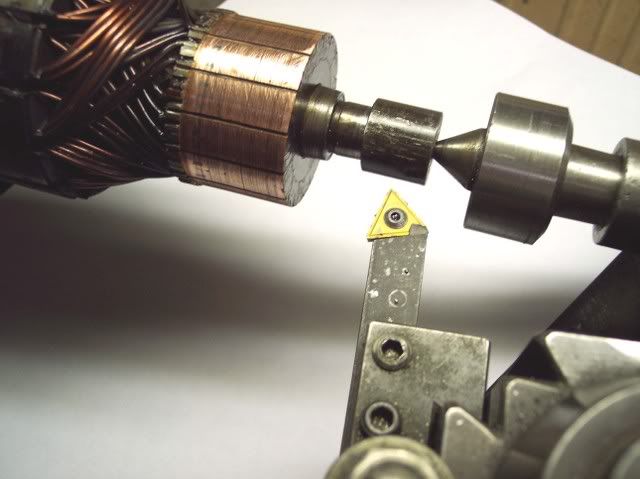

I was using my loader on my 1976 MTD 990 tractor clearing my elderly neighbors driveway of snow when my starter generator started making a loud grinding sound. It lasted for only a few seconds but it did this a few times. I oiled the bearing and continued the job. I removed the S/G and took it apart. The shaft at the bronze bearing was worn down to a taper from 9/16" dia. to 1/2" dia. and about 5/8" long. The bronze bearing was shot, way over 9/16" dia. ID. I had a replacement bearing and installed it on the end plate. I had to machine a slot on the side for the felt packing that brings up oil from the pocket below. I removed the front face plate on the S/G and placed the windings in my lathe. I turned the shaft down so I could press fit a sleeve.

I then remachined the end to 9/16" dia. (.562 dia.)

I reassembled everything and installed it on the tractor. It work perfect. It saved me about $100 plus shipping for a new one on Ebay. I'm glad I had a lathe to do the work.