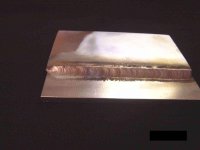

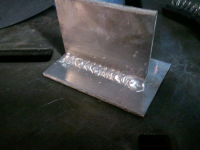

I figure if I ever need to weld aluminum then I simply may try it this way. While recommended practice is to use AC square wave and high frequency to tig aluminum (I do not have those): This fella is using plain ole DC scratch start tig torch and using the SMAW stick rods for filler (instead of normal tig filler wire). Supposedly the flux on the SMAW stick rods helps make up for the cleaning action that you are otherwise lacking by not having AC square wave or high freq. I am sure it is an improvisation, but I simply have very little need (actually zero need) to weld aluminum so do not even want to bother with a Teflon liner in my little mig and fighting the birds nests due to lack of spool gun.

(note: While this fella is using an inverter welder, any ole scratch start tig rig on a transformer would suffice for this method as well).

TIG Welding of aluminum with a DC inverter - YouTube