I broke the top link while using a subsoiler with my Kioti DK40SEH HST I guess I did something wrong with the 2nd lever that adjusts the float for the 3 pt hitch any suggestions as to what I did wrong and what I should do to avoid this again, I imagine I could have done more damage then I did.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

sub soiler broke top link

- Thread starter derek01

- Start date

- Views: 7603

More options

Who Replied?

/ sub soiler broke top link

#1

jinman

Rest in Peace

- Joined

- Feb 23, 2001

- Messages

- 21,059

- Location

- Texas - Wise County - Sunset

- Tractor

- NHTC45D, NH LB75B, Ford Jubilee

Derek, please explain how the toplink broke. Did it just snap off or did it bend into a banana shape? When you are digging with a subsoiler, the pressure on the toplink is all compression. I'm inclined to say you had a faulty toplink, but a photo or more details might help us to better evaluate your failure.

jonyyuma

Elite Member

- Joined

- Sep 14, 2010

- Messages

- 2,922

- Location

- 35 miles North of Memphis,TN

- Tractor

- kubota L3000dt, ford 8n1952

I know that that little blade is like pulling an anchor..Talk about planting a tractor and making the govenor work???I have to wonder how many Mules it would take to pull it ?

I will bring the top link to the shop tomorrow (forgot to bring camera home) thats all that left to take photo of it is slightly bent it broke both the female and male parts of the top link. I really do not under stand the float lever for the 3 pt hitch. The subsoiler was very deep and if I remember right it was angled with the top tilted toward the tractor I think it pulled down too deep? Still the top should not have busted right. I thought the top link was maybe faulty (even though I have been using it for 2 years) until I broke the second one. I wish I had taken photo of the whole thing busted in place.

JohninCT

Platinum Member

I will bring the top link to the shop tomorrow (forgot to bring camera home) thats all that left to take photo of it is slightly bent it broke both the female and male parts of the top link. I really do not under stand the float lever for the 3 pt hitch. The subsoiler was very deep and if I remember right it was angled with the top tilted toward the tractor I think it pulled down too deep? Still the top should not have busted right. I thought the top link was maybe faulty (even though I have been using it for 2 years) until I broke the second one. I wish I had taken photo of the whole thing busted in place.

I believe that you are referring to the draft control lever. On my Kioti DK 40 the position control lever is the red outside one and the inside yellow lever is the draft control. I've only played with the draft control a little and don't really use it much, but I'll try to explain how it works. There are 3 holes at the tractor for the top link to connect to. Look in your owners manual. The bottom two are for draft control use (bottom light load, middle heavy load, top no draft control). Connect your top link to the middle hole. Start by putting both levers the all the way forward then back off the yellow lever to the depth that you want the subsoiler to maintain. When it pulls through a hard spot in the ground the draft control senses the added load and raises the implement up to pull easier. Then it will lower back down to maintain the set depth. You may also have to slow down the 3 point lowering speed using the speed control knob below the seat so that automatic draft control will not be jerky.

Somebody please chime in here if I've mistated or missed any info on using the draft control.

I used the top hole, if you look closely at the break you will see that it was bent slightly. I understand that the 2 lower holes are for the draft but it seems that every time I adjust the yellow lever the hitch either will not go up high enough or down low enough especially when I am using rear lever for the 3 pt hitch.

Attachments

JDGreenGrass

Veteran Member

If it was bent before it broke I am sure that contributed to the breakage.

Did you hook on to a root or a rock.?? How fast were you going.??

A sub-soiler definitely puts a lot of stress on the top link, as you are now aware, I'm sure.

Did you hook on to a root or a rock.?? How fast were you going.??

A sub-soiler definitely puts a lot of stress on the top link, as you are now aware, I'm sure.

Gator6x4

Super Star Member

My two cents worth. The subsoiler does not have a shear pin and the top link acted as one. If the top link had not broken the mounting point for the top link on the tractor would have been pushed in making for a very expensive repair. I have often wondered when looking at subsoilers without a shear pin or tripping mechanism offered at some retail locations how much damage would occur if a solid object was encountered. I would be thankful the toplink is what broke and explore other options on how to insure when the subsoiler encounters a solid object under ground it trips and does not break the tractor housing.

Baby Grand

Elite Member

- Joined

- Nov 12, 2007

- Messages

- 4,663

- Location

- Windsor, CT.

- Tractor

- Kubotas: L3240GST B2320HST B5100D & G5200H

My two cents worth. The subsoiler does not have a shear pin and the top link acted as one. If the top link had not broken the mounting point for the top link on the tractor would have been pushed in making for a very expensive repair. I have often wondered when looking at subsoilers without a shear pin or tripping mechanism offered at some retail locations how much damage would occur if a solid object was encountered. I would be thankful the toplink is what broke and explore other options on how to insure when the subsoiler encounters a solid object under ground it trips and does not break the tractor housing.

I have one of the TSC variety and have hooked onto something big a few times and only lost traction as a result. Once so abruptly that I thought I was going to go over the hood. Shear bolt of some sort would be prudent, and not terribly difficult to add. Since the top link is in compression, any off axis load will tend to buckle it - a slight bend would do it, as would excessive slop in the threads. When using mine, I try to adjust the hitch so the big beam/mast is as close to vertical as I can get it when it's at working depth.

JohninCT

Platinum Member

I used the top hole, if you look closely at the break you will see that it was bent slightly. I understand that the 2 lower holes are for the draft but it seems that every time I adjust the yellow lever the hitch either will not go up high enough or down low enough especially when I am using rear lever for the 3 pt hitch.

If you are using the top hole you should not be adjusting the yellow draft control lever at all. Leave the yellow lever all the way forward (deepest setting) and control the raise and lower of your implement with the red position control lever only. Since your tractor has draft control (not all do) you should maybe give it a try when using a ground engaging implement like the subsoiler. It's hard to say, but the automatic draft control may have prevented the overload failure of your top link.

jinman

Rest in Peace

- Joined

- Feb 23, 2001

- Messages

- 21,059

- Location

- Texas - Wise County - Sunset

- Tractor

- NHTC45D, NH LB75B, Ford Jubilee

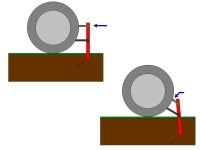

Derek, from the looks of your toplink break, I think it was being bent and compressed at the same time. I've attached an illustration of what I think may be the culprit.

When you are shallow with the subsoiler, the compression pressure is straight along the axis of the toplink. As the subsoiler goes deeper into the ground, the pressure becomes not only compression, but a bending force as well. I think your toplink is just not strong enough to take the bending force caused by your subsoiler, especially if you hit a root and it got an impact load.

When you are shallow with the subsoiler, the compression pressure is straight along the axis of the toplink. As the subsoiler goes deeper into the ground, the pressure becomes not only compression, but a bending force as well. I think your toplink is just not strong enough to take the bending force caused by your subsoiler, especially if you hit a root and it got an impact load.

Attachments

eray1066

Bronze Member

- Joined

- Jun 2, 2009

- Messages

- 74

- Location

- RI, MA

- Tractor

- Challenger MT285B, Kubota L4150 , Farmall super A, Farmall Cub

My son in law did this same thing earlier this year. He borrowed a subsoiler from another farm and used it with a 47 HP Challenger MT285B (same as MF 1547). The geometry of the three point hitch allowed the top link to go over center when lowered way down. The force allowed the subsoiler and the top link to be too straight and the angle between the subsoiler and the top link went from a V to an inverted V. When the 3 PTH was raised all **** broke loose. The solution was to change the hole on the tractor where the top link is attached so that it always is parallel to the lower lift arms.

Bought a new top link @ TSC returned the borrowed unit and bought a larger subsoiler at TSC. Lots of use ...... no problems.

Bought a new top link @ TSC returned the borrowed unit and bought a larger subsoiler at TSC. Lots of use ...... no problems.

orezok

Super Member

Derek, from the looks of your toplink break, I think it was being bent and compressed at the same time. I've attached an illustration of what I think may be the culprit.

When you are shallow with the subsoiler, the compression pressure is straight along the axis of the toplink. As the subsoiler goes deeper into the ground, the pressure becomes not only compression, but a bending force as well. I think your toplink is just not strong enough to take the bending force caused by your subsoiler, especially if you hit a root and it got an impact load.

I don't see how a "bending" would occur as there is no moment connection if the clevis does not bottom out. The force will continue to be exerted straight along the toplink. However, the amount of force on the toplink would increase due to the change in relationship of the length of the "lever" below the 3 point connection and the diminished length above.

oldballs

Elite Member

- Joined

- Dec 29, 2009

- Messages

- 4,536

- Location

- Kansas...USA

- Tractor

- Kubota B2620 , Case 448 , Kubota B2650

Maybe the angle of the snag and the tension on the check chains were such that the "bend" occurred with the compression force. .... really, I'm no engineer.

Last edited:

Baby Grand

Elite Member

- Joined

- Nov 12, 2007

- Messages

- 4,663

- Location

- Windsor, CT.

- Tractor

- Kubotas: L3240GST B2320HST B5100D & G5200H

I don't see how a "bending" would occur as there is no moment connection if the clevis does not bottom out. The force will continue to be exerted straight along the toplink. However, the amount of force on the toplink would increase due to the change in relationship of the length of the "lever" below the 3 point connection and the diminished length above.

Exactly right - well put.

Since there's a "pinned joint", the top link is in pure compression, no bending load applied. Any looseness of the thread could allow a kink or curve in the toplink and add a bending load - so always tighten up the adjusting nut when running ground engaging implements. If the top link dead straight and rigid, then the risk to top link is only buckling due to compressive overload.

Angle above 90 degrees (call it A) between subsoiler & top link magnifies the compressive load - same principle that makes a chain binder work so well.

Compressive load in the top link = Load at the pin * (1/cos A).

I think the OP mentioned that the top link was already slightly bent before pulling the subsoiler, so the combination of bent link + binder effect of the angle was probably much. I don't think there's anything wrong with the subsoiler.