Has anyone built a suspended concrete floor for a workshop before?

I am prepping for a 12 ft x 24 ft tool shed. Because of the creek and floodplain, the floor will need to be about 3 ft above the ground. My original thoughts were to build a wood floor. But, since I do alot of welding I decided I don't want a combustible floor.

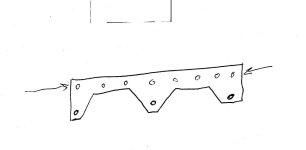

The building will be all steel pole building style with 3'' pipe and C-purlin construction. The floor would be supported by vertical 3'' pipe on 6 ft centers and floor joists of 8'' purlin on 24'' centers. If I do a concrete floor, my thoughts are to install 26 guage R-panel galvalume to the top of the 8'' purlins and ring it with 4'' purlins. This would allow for a 4'' thick concrete slab with #3 rebar at 18'' centers. I am also thinking of dividing the floor with additional 4'' perlins at 3 ft centers (divide the concrete into four 3 ft x 12 ft sections). The extra 4'' purlin would give me additional attachment points for equipment.

Any thoughts or suggestions?

I am prepping for a 12 ft x 24 ft tool shed. Because of the creek and floodplain, the floor will need to be about 3 ft above the ground. My original thoughts were to build a wood floor. But, since I do alot of welding I decided I don't want a combustible floor.

The building will be all steel pole building style with 3'' pipe and C-purlin construction. The floor would be supported by vertical 3'' pipe on 6 ft centers and floor joists of 8'' purlin on 24'' centers. If I do a concrete floor, my thoughts are to install 26 guage R-panel galvalume to the top of the 8'' purlins and ring it with 4'' purlins. This would allow for a 4'' thick concrete slab with #3 rebar at 18'' centers. I am also thinking of dividing the floor with additional 4'' perlins at 3 ft centers (divide the concrete into four 3 ft x 12 ft sections). The extra 4'' purlin would give me additional attachment points for equipment.

Any thoughts or suggestions?