marting

New member

Hi all,

I have just acquired my first tractor - a Kioti CK4210 to help manage our little hobby farm in Australia.

With the ROPS up it is too tall to fit through the door of my shed where I'd like to park it. I've worked out how to fold it down but the way it's setup makes this quite time consuming.

Since this is a safety feature and I'm quite new to tractors I had a couple of questions around this.

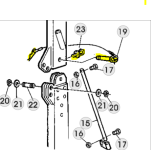

They way it was delivered there is a bolt+nut in the top hole that locks it in place and a pin with a handle in the hinge slot lower down. I'll attach pictures if it lets me.

Given the lock bolt is the one that has to come out to fold it and the hinge pin stays in place this seems backwards. Can anyone see a reason it would be setup this way? I'd like to just be able to pull out 2 pins, fold, replace pins instead of getting out 2 wrenches.

They are easy to swap so next question would be if there are any safety concerns in doing that? For instance is the upper locking hole more structurally significant than the hinge? I don't know how to evaluate the strength of the pin vs the bolt. I've read about grades 2,5,8 on this forum but we don't use that system here. The bolt has 7T DS written on it; I did not notice any markings on the pin. What kind of pin would I need to be at least as strong as a 7T bolt?

Lastly as it was delivered those lock bolts were extremely tight. Took 2 people with extended leverage wrenches to get it loose. Is the tightness of these bolts a significant factor in performance of the rops? They have nylon lock nuts so don't think they'll come loose on their own. I've not made them as tight now and it leaves the rops with a small amount of forward/backward free play which I can compensate for by pushing it back with the little knock bolt at the front but it leaves it sitting at a very slight angle instead of straight up. Would that be a problem?

Thank you for reading and any advice you can share.

-Martin.

I have just acquired my first tractor - a Kioti CK4210 to help manage our little hobby farm in Australia.

With the ROPS up it is too tall to fit through the door of my shed where I'd like to park it. I've worked out how to fold it down but the way it's setup makes this quite time consuming.

Since this is a safety feature and I'm quite new to tractors I had a couple of questions around this.

They way it was delivered there is a bolt+nut in the top hole that locks it in place and a pin with a handle in the hinge slot lower down. I'll attach pictures if it lets me.

Given the lock bolt is the one that has to come out to fold it and the hinge pin stays in place this seems backwards. Can anyone see a reason it would be setup this way? I'd like to just be able to pull out 2 pins, fold, replace pins instead of getting out 2 wrenches.

They are easy to swap so next question would be if there are any safety concerns in doing that? For instance is the upper locking hole more structurally significant than the hinge? I don't know how to evaluate the strength of the pin vs the bolt. I've read about grades 2,5,8 on this forum but we don't use that system here. The bolt has 7T DS written on it; I did not notice any markings on the pin. What kind of pin would I need to be at least as strong as a 7T bolt?

Lastly as it was delivered those lock bolts were extremely tight. Took 2 people with extended leverage wrenches to get it loose. Is the tightness of these bolts a significant factor in performance of the rops? They have nylon lock nuts so don't think they'll come loose on their own. I've not made them as tight now and it leaves the rops with a small amount of forward/backward free play which I can compensate for by pushing it back with the little knock bolt at the front but it leaves it sitting at a very slight angle instead of straight up. Would that be a problem?

Thank you for reading and any advice you can share.

-Martin.