pacrotcart said:

Plus, the split we found in the new seal was about a sixteenth inch long and I can't see how that much fluid was going out through that little hole.(a cup every 4 or 5 seconds!) At least thats how much was coming out the top of the engine!

If you compute how much oil the pump is producing at normal RPM, it's about 2.6 cups per second based on 9.8 gpm capacity. When the system is pressurized under use like using the 3PH or FEL, the system pressure of 2500 psi can push lots of oil through a tiny hole. For my hydraulic remotes, I have 0.030" orifices inline so I can control the speed of hydraulic cylinders. An uncontrolled hole 1/16" is equal to an orifice size of 0.062" or about twice the size of the orifices in my hydraulic lines. So, my answer is yes, you can easily push a cup every 4-5 seconds out a tiny hole like that.

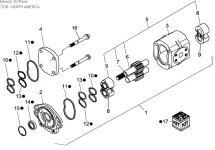

Below, I've included a photo of my pump with a blown outer seal. It's larger than 1/16", but the outer seal is not a pressure seal as I said before. The entire pump inner seals are shown in the illustration. Parts #10 thru #15 are supposed to be included in the repair kit #17. The two big seals are item #11. Items #10 are bushing seals and item #13 is the backup ring. Item #7 is the gear pump and item #6 is the driving gear. So yes, the wear blocks (items #8&9) must be removed and all the seal components replaced.

The Repair Manual says to inspect all components for excess wear and scoring after disassembly. All these steps and what to look for are why I decided to have my dealer's shop rebuild my pump. I figured they knew just what to look for and all the tricks to make a successful job. I know you are trying to save money, so was I. I did all the pump removal and re-installation, but figured the cheapest way to get a good seal job was to let somebody else do the job. I don't mean to lecture you, but rather just tell you where my head was when I fixed my pump. I understand your frustration now, but that outer seal blowing is evidence that something is wrong with the internal seals. You'll have to tear it down again. Sorry. . .

EDIT: Of course, you could also have a problem with the power steering pump. Do you have the pump with the separate reservoir or does your PS pump draw fluid from the main reservoir? If you have a separate reservoir, checking the fluid level there will verify that the PS pump is fine. Those two pumps are the only source of hydraulic oil into the engine. Also, the hydraulic oil won't hurt your engine as long as you drain it down to normal levels. Multi-G 134 is a multi-grade oil/lubricant. I would not run it instead of engine oil for extended times, but until you know for sure your pump is going to hold, I'd just drain the excess oil down to normal levels in the engine and run it to test. I WOULD NOT change engine oil and filter every time I was testing. Save that job until you are sure your main pump seals are holding.