k0ua

Epic Contributor

Re your pto shaft. The telescope section needs greasing, it looks dry. Also when did the universal joints get greased last?

I did not notice that, but yeah, dry as a bone, and I bet the U joints are dry too.

Re your pto shaft. The telescope section needs greasing, it looks dry. Also when did the universal joints get greased last?

I'm of the opinion that the cover on a rotary cutter PTO shaft is a waste of money. Nobody should ever have a reason to get anywhere near to a rotating shaft on a rotary cutter. It's not like a post-hole auger or chipper where you work close to an operating shaft. I think the same way about a tiller or other piece of PTO driven equipment. It's my opinion for what it's worth. Some safety features are overkill in my estimation. The points about lubing the shaft are valid, but I can't be sure the U-joint isn't greased. I'm not sure that Ridgewalker has had the mower or tractor very long.

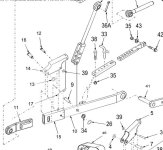

One thing for sure, the extendable arms on the 3PH need lots of attention. Don mentioned that the "dust cover" was missing off the left side. That is NOT a dust cover. It is a spring loaded release sleeve that operates the bolt that drops into the slot on the extendable arm section. The front of the cover has a spring under it. You press down on the front of the cover and it pivots on the front pin and raises the locking bolt out of the slot. When you release the sleeve, the spring pushes it back up and locks the extendable arm when it moves forward to the operating position. Don's left side extendable link must be locked in place or the locking bolt is loose enough to move up and down by hand. If that's the case, only gravity and weight of the bolt is holding it in place. I can see on the left arm that the front pivot pin is completely gone as is the sleeve and spring. See the illustration below.

View attachment 332242