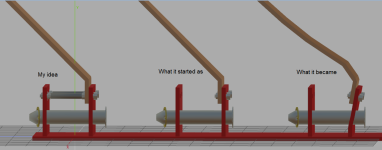

I'm on my third seasons of mowing with my Titan, and I am running into problems. The 3-point triangle keeps bending and has split the metal at the seam. I welded it twice so far, but it splits again because the place where the lift arms attach is bending outward (see pics). I have gone through some steps to reduce this, but the fact is, my land has a lot of hills, angles, and bumps. When I turn around to mow the other direction, the whole mower shifts "downhill" to the other side and incrementally bends the upper most plate. When that plate bends, the angles meeting at the upper 3pt arm bend as well. I've added some bent lines to the images to indicate how they are bending.

The inner plate doesn't bend because they're not connected. I guess the metal is too weak or I am beating it up too hard. . I am considering welding a bar to connect the two plates that hold the lift arm pin. (green line on second picture). Alternatively, I am considering bending the upper arm angled pieces to connect to the inner plate instead of the outer plate. At least that way, the constant slamming of that outer plate wouldn't effect the angled pieces.

I am just trying to prolong the mower's life because the hammers and drive train seem to be working fine. For my next purchase, I will have to more closely look at the design of better flail mowers or consider buying an old-school bushhog.

I did just look at the

Woodmaxx 62 and it looks like it has the same kind of upper -arm tree connection as the Titan. How can I be sure I won't bend that as well?